- Joined

- Feb 2, 2014

- Messages

- 1,069

I was doing some shop cleanup and organizing the other day and ran across this crank shaft that I had made close to 3 years ago. At that time I had built a flat twin engine that did run but not very well. After a lot of fiddling around and some disappointments I decided to use some of the parts off that engine for my 90 degree v-twin engine. That engine turned out to be very reliable and a good runner.

I thought maybe I should take another shot at building a horizontal twin engine I can't just throw the crank away.

I found a pair of piston and rod assembles that I had made for a different engine at some time and remade the connecting rod bearings to fit this crank.

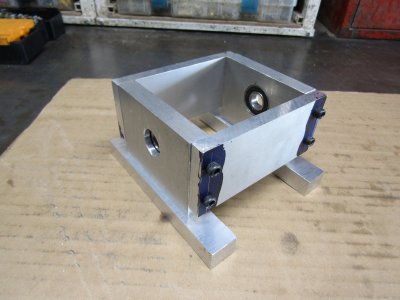

This might be a good time to experiment on a bolt-together engine. No castings or large lumps of aluminum just flat plates screwed together in a simple way.

Since the crank, rods, and pistons are already made I will have to build around these parts.

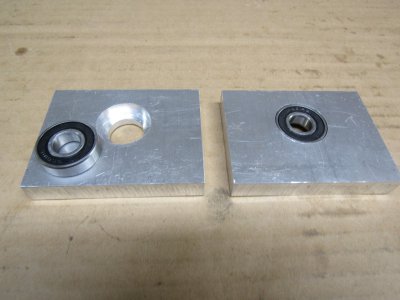

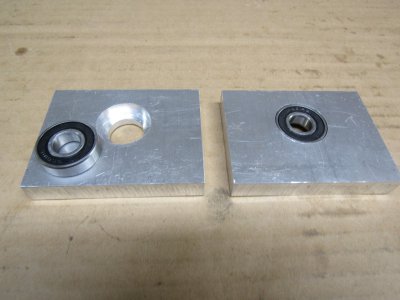

I started with a couple of 1/2" aluminum plates and installed a ball bearing in each.

So here is the starting point.

1" bore and 1" stroke.

Thanks for looking

Ray

I thought maybe I should take another shot at building a horizontal twin engine I can't just throw the crank away.

I found a pair of piston and rod assembles that I had made for a different engine at some time and remade the connecting rod bearings to fit this crank.

This might be a good time to experiment on a bolt-together engine. No castings or large lumps of aluminum just flat plates screwed together in a simple way.

Since the crank, rods, and pistons are already made I will have to build around these parts.

I started with a couple of 1/2" aluminum plates and installed a ball bearing in each.

So here is the starting point.

1" bore and 1" stroke.

Thanks for looking

Ray