Hey guys! I will be getting in to the awesome hobby of machining. My experience level is basically none. I have done some drilling with a mill/drill at work. I have a 4x6 bandsaw, a welding machine, a harbor freight 13" drill press, and many other various tools. I have been looking at this point for 1.5 yrs at my many options. I have looked at some CNC options and don't think it's an option ATM. I want a good lathe and mill. A RF45 is the minimum I will go for a bench mill. I would like a dro for both, but I need tooling, vises, turn table, dial indicators, test indicators and everything else. I am not expecting anyone to list everything one would need to get started, I just want you guys keep that I mind when suggesting tools. The budget is $10K and nothing will be added for a while since I had to negotiate this budget with my wife. I don't think she will be receptive to adding other machine cost any time soon. I will be making this purchase April 2015 so I still have plenty of time to do more research. I will be cross posting this between the Grizzly forum so let's keep this centered on Precision Matthews products if possible. Thanks for your time and help!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help me spend my future budget! Help a newbie out!!

- Thread starter Earlkonig

- Start date

- Joined

- Mar 12, 2014

- Messages

- 1,531

To help us give you a better idea on machines and tooling could you give us some idea of what exactly you will be machining. Anything such as items or sizes will be helpful to recommend size of machines as well as accessories.

Definitely. I have interest in model engine building, gun smithing, custom PC water cooling, 3d printing, robotics, some automotive projects, make repair parts for some old farm equipment we have, and other misc. projects. I know this is a pretty broad list and materials will vary. I would think steel, aluminum, copper and maybe titanium after I get a class d fire extinguisher. Also I have an interest in knife making. Sorry if this doesn't help and I appreciate your time.

- Joined

- Sep 19, 2012

- Messages

- 3,063

Hello fellow Hendersonian! When you talk the missis into the funds, look me up for a helping hand.

Jake Parker

Jake Parker

- Joined

- Nov 24, 2013

- Messages

- 1,791

Before I looked at any machine I would make a list of every toy you want. Like rotary table, dividing head, mag base, etc, etc. Everything. Then price it all for what you intend to buy. Dont price a harbor fright indicator if you plan on a starrett. The subtract that money right from the top. Then from there you can find your machine budget. I see alot of guys blow it all on machines and cant buy a vise.

I think I would consider a pm45 though if it fit the budget. Or bigger. But the 45 comes in a cnc version so I would suspect a conversion down the road would be easy. Though the price I seen for the 45 already cnc was really nice.

I think I would consider a pm45 though if it fit the budget. Or bigger. But the 45 comes in a cnc version so I would suspect a conversion down the road would be easy. Though the price I seen for the 45 already cnc was really nice.

- Joined

- Mar 12, 2014

- Messages

- 1,531

Okay we at least maybe have a starting point to get input and get a conversation going on sizes and products.

You mentioned farm equipment and automotive as the largest work envelope. If you are looking at an absolute maximum of $10k to include lathe, mill and tooling/accessories I am assuming you are looking at Chinese equipment. Taiwanese equipment would put you over that with just the lathe and mill without any tooling to use.

Based on your work envelope I would say a 12x36 as your minimun size lathe and I would suggest the PM45PDF to encompass the work envelope as far as milling machine. The PM1236 is a very popular choice among many forum members and has high reviews. If you could swing something just a tad lager the PM1440E-LB has a larger spindle bore and there are some members on here who have just taken delivery of theirs and they appear to be well equipped.

Hopefully some members who have these machines will chime in and give personal first hand experiences.

You mentioned farm equipment and automotive as the largest work envelope. If you are looking at an absolute maximum of $10k to include lathe, mill and tooling/accessories I am assuming you are looking at Chinese equipment. Taiwanese equipment would put you over that with just the lathe and mill without any tooling to use.

Based on your work envelope I would say a 12x36 as your minimun size lathe and I would suggest the PM45PDF to encompass the work envelope as far as milling machine. The PM1236 is a very popular choice among many forum members and has high reviews. If you could swing something just a tad lager the PM1440E-LB has a larger spindle bore and there are some members on here who have just taken delivery of theirs and they appear to be well equipped.

Hopefully some members who have these machines will chime in and give personal first hand experiences.

- Joined

- Sep 19, 2012

- Messages

- 3,063

Are you deadset on new, or if the price was right would you consider used?

Jake Parker

Jake Parker

Hello fellow Hendersonian! When you talk the missis into the funds, look me up for a helping hand.

Jake Parker

WOW! This is a small world. When the time comes DEFINITELY! This will make this a little easier having someone close by that can help out. Do you have any PM equipment Jake? If so and you dont mind it would be pretty awesome to lay eyes on something before I buy.

Before I looked at any machine I would make a list of every toy you want. Like rotary table, dividing head, mag base, etc, etc. Everything. Then price it all for what you intend to buy. Dont price a harbor fright indicator if you plan on a starrett. The subtract that money right from the top. Then from there you can find your machine budget. I see alot of guys blow it all on machines and cant buy a vise.

I think I would consider a pm45 though if it fit the budget. Or bigger. But the 45 comes in a cnc version so I would suspect a conversion down the road would be easy. Though the price I seen for the 45 already cnc was really nice.

Chuck I am working on a spread sheet since I have so much time on my hands between now and march. I have been slowly adding things here and there just for the reason you said. I could by a chinese bp clone, but probably wouldnt have enough money to get everything else.

Before I looked at any machine I would make a list of every toy you want. Like rotary table, dividing head, mag base, etc, etc. Everything. Then price it all for what you intend to buy. Dont price a harbor fright indicator if you plan on a starrett. The subtract that money right from the top. Then from there you can find your machine budget. I see alot of guys blow it all on machines and cant buy a vise.

I think I would consider a pm45 though if it fit the budget. Or bigger. But the 45 comes in a cnc version so I would suspect a conversion down the road would be easy. Though the price I seen for the 45 already cnc was really nice.

Okay we at least maybe have a starting point to get input and get a conversation going on sizes and products.

You mentioned farm equipment and automotive as the largest work envelope. If you are looking at an absolute maximum of $10k to include lathe, mill and tooling/accessories I am assuming you are looking at Chinese equipment. Taiwanese equipment would put you over that with just the lathe and mill without any tooling to use.

Based on your work envelope I would say a 12x36 as your minimun size lathe and I would suggest the PM45PDF to encompass the work envelope as far as milling machine. The PM1236 is a very popular choice among many forum members and has high reviews. If you could swing something just a tad lager the PM1440E-LB has a larger spindle bore and there are some members on here who have just taken delivery of theirs and they appear to be well equipped.

Hopefully some members who have these machines will chime in and give personal first hand experiences.

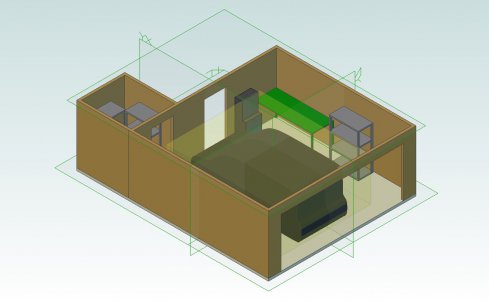

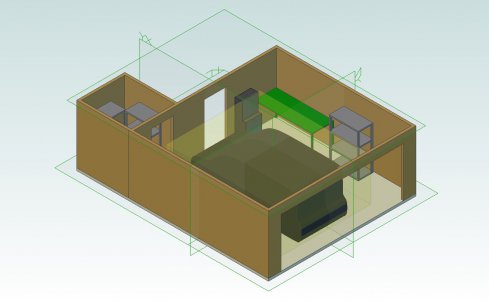

I was leaning towards the PM1236 and PM45PDF. How would a PM45PDF stack against a smaller style knee mill like the PM836? Space is semi limited as in i have 50" for the wall to where a negotiated boundary in the garage that leaves my wife room to walk around. Against that wall I have 18ft. Just a heads up.

Thanks.

Are you deadset on new, or if the price was right would you consider used?

Jake Parker

Not against used at all. I have no experience on what would be a great buy and what would be a disaster. I heard that getting ways scraped could make a lot of "deals" found turn into money pits. I guess my apprehension is my own ignorance. IF someone could point me to some good, ready to go equipment, I would be willing to at least look that route.

Hi, and welcome to Hobby Machinist forum... I think you will find lots of friendly folks here who will listen and suggest things.

I came to this forum in early July... I was at a similar place to you... albeit the machining goals were different.

I fiddle with and fly EAB aircraft (think barnstormers... LOL), as well as making non-aviation related custom parts for folks.

I started with a desire for a PM1127 and a PM25 (well, the preceding mill to the PM25... Matt improved the product, it is now called the 25). Then after a lot of study... decided to upgrade to a PM932/PDF (a nicer version of a PM45). Then decided to upgrade to a 1236 lathe. This kinda fit my budget... until I got to looking at the machines in person (local folks)... First I bit the bullet and upgraded to the 1340GT lathe... then after a few weeks of indecision upgraded to the PM935TS mill. Both of these are Taiwanese made machines, the quality is a HUGE step up.

IMO these three combinations are good groups:

1127 and 25

1236 and 45/932

1340GT and 935TS/TV

Depending on whether your needs are mill or lathe intensive... might mix and match.

From someone that has studied this for close to 4 months...

Your budget may be a little soft...

With around $10K:

You can get the 1127/25 with lots of tooling

You can get the 1236/45-932 with a little tooling

Or you cannot get the 1340/935 for even more than your budget with no tooling

Now lets talk a little about machine size: The reason a machine tool is massive and heavy is something called chatter.

The operation of cutting metal is in reality somewhere between chiseling and scraping... precisely controlled gouging might be a sloppy way to invision it. The more DOC (depth of cut) one takes, the more the tool tends to want to vibrate (or chatter). Now cast iron is really good at absorbing that chatter, so it does not result in a wavy and rough finish of the cut.

The little machines will take little cuts, but chatter with larger cuts.

The middle machines will offer some more strength while taking deeper cuts

The Taiwanese pair noted above, will take a little more DOC, yet do it with more precision... and they are just built to tighter standards. Note the 1340GT G=gunsmithing, T=Taiwanese

While we are talking about precision and accuracy: Something to understand: The ability to make a precision part (hold tight tolerances) is as much--if not more--the operator... than the machine... and this takes lots of time to learn.

However a well made and well maintained machine helps.

If it were me... given your list of things you want to do...

I would look seriously at the 1236/45-932 (with the PDF feature)... and figure on spending more as you need specific tooling.

You can start off with not a lot of tooling (you will need measuring tools and basic cutting tools)... then add things (rotary table) as you need them.

BTW: Amazon has lots of stuff, and it is relatively competitive (not machines, tooling). Get a Prime account... freight is free.

Here is a thought: You can always get more tooling... however it is hard to get more machine without upgrading...

And here is something to consider: QUALITY!

Matt's PrecisionMatthews machines are subtly a cut above... little details which become quite noticeable if they are missing. And Matt is a wonderful guy to work with. If it were me, I would not let flashy deals get my attention... one usually gets what they pay for... regardless of the fluff.

Hope all this helps, please feel free to ask all the questions you want... someone will do their best to answer them.

I came to this forum in early July... I was at a similar place to you... albeit the machining goals were different.

I fiddle with and fly EAB aircraft (think barnstormers... LOL), as well as making non-aviation related custom parts for folks.

I started with a desire for a PM1127 and a PM25 (well, the preceding mill to the PM25... Matt improved the product, it is now called the 25). Then after a lot of study... decided to upgrade to a PM932/PDF (a nicer version of a PM45). Then decided to upgrade to a 1236 lathe. This kinda fit my budget... until I got to looking at the machines in person (local folks)... First I bit the bullet and upgraded to the 1340GT lathe... then after a few weeks of indecision upgraded to the PM935TS mill. Both of these are Taiwanese made machines, the quality is a HUGE step up.

IMO these three combinations are good groups:

1127 and 25

1236 and 45/932

1340GT and 935TS/TV

Depending on whether your needs are mill or lathe intensive... might mix and match.

From someone that has studied this for close to 4 months...

Your budget may be a little soft...

With around $10K:

You can get the 1127/25 with lots of tooling

You can get the 1236/45-932 with a little tooling

Or you cannot get the 1340/935 for even more than your budget with no tooling

Now lets talk a little about machine size: The reason a machine tool is massive and heavy is something called chatter.

The operation of cutting metal is in reality somewhere between chiseling and scraping... precisely controlled gouging might be a sloppy way to invision it. The more DOC (depth of cut) one takes, the more the tool tends to want to vibrate (or chatter). Now cast iron is really good at absorbing that chatter, so it does not result in a wavy and rough finish of the cut.

The little machines will take little cuts, but chatter with larger cuts.

The middle machines will offer some more strength while taking deeper cuts

The Taiwanese pair noted above, will take a little more DOC, yet do it with more precision... and they are just built to tighter standards. Note the 1340GT G=gunsmithing, T=Taiwanese

While we are talking about precision and accuracy: Something to understand: The ability to make a precision part (hold tight tolerances) is as much--if not more--the operator... than the machine... and this takes lots of time to learn.

However a well made and well maintained machine helps.

If it were me... given your list of things you want to do...

I would look seriously at the 1236/45-932 (with the PDF feature)... and figure on spending more as you need specific tooling.

You can start off with not a lot of tooling (you will need measuring tools and basic cutting tools)... then add things (rotary table) as you need them.

BTW: Amazon has lots of stuff, and it is relatively competitive (not machines, tooling). Get a Prime account... freight is free.

Here is a thought: You can always get more tooling... however it is hard to get more machine without upgrading...

And here is something to consider: QUALITY!

Matt's PrecisionMatthews machines are subtly a cut above... little details which become quite noticeable if they are missing. And Matt is a wonderful guy to work with. If it were me, I would not let flashy deals get my attention... one usually gets what they pay for... regardless of the fluff.

Hope all this helps, please feel free to ask all the questions you want... someone will do their best to answer them.

Last edited:

- Joined

- Apr 1, 2013

- Messages

- 1,142

If you can when you get ready to buy hold a bit of your budget back so once you are set up and realize you will need this or that you still have the funds.Consider HSS instead of Carbide in the begining, cheaper more flex able. Also leave room for books. I found reading up on basic machining help me understand what feature, and tools were needed, what could be built at home, and what could wait. Don't be fraid to check e-bay and creigs list for deals. I started with just a lathe and later added a mill. slowly have been adding thing ever since. Mark