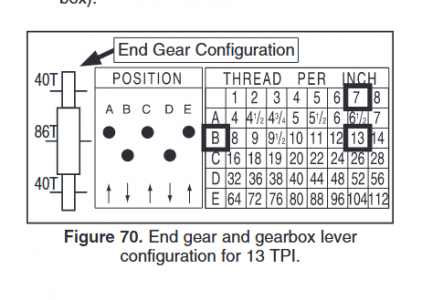

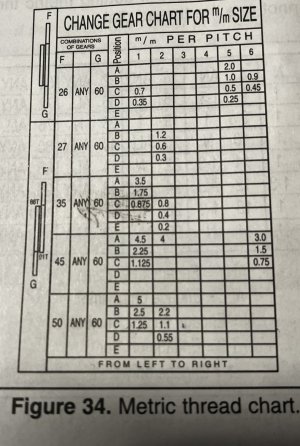

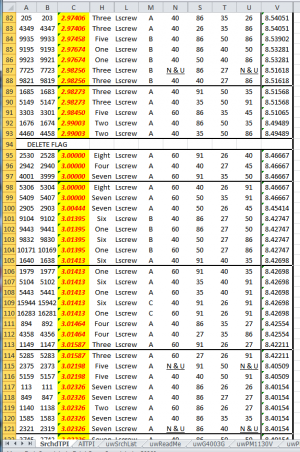

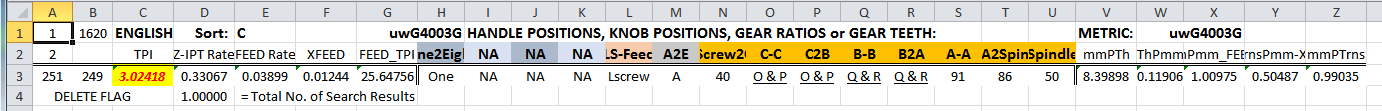

So I am a little confused. I thought I had used the gear box plate for the G4003G, but maybe it was the G4003 (which I cannot see in the manual). So your are saying that these two have different Norton Gear boxes??? The manuals that I downloaded were not clear. Please post a picture of the gear plate that is on your lathe so I can check and tell me what the upper and lower gear tooth numbers were to get this plate.My lathe is a G4003G which has a different gearbox, the combo of 40 up top and 60 below in position 2A is finer than 3.0

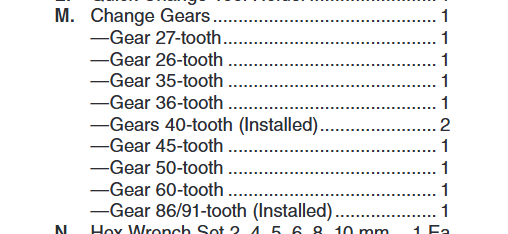

The manual for the G4003G says that you should have the following gears and it shows the plate for TPI in the screen grabs below. Are these not what you have on your lathe? The plate that is shown indicates that the gear box I built into the spread sheet should work. 40 top, 40 bottom, A-1 yields 4TPI. Likewise for all of the other numbered lever positions. The A, B, C, D, E are just factors of two so that would be all that is necessary to check out the gear box.

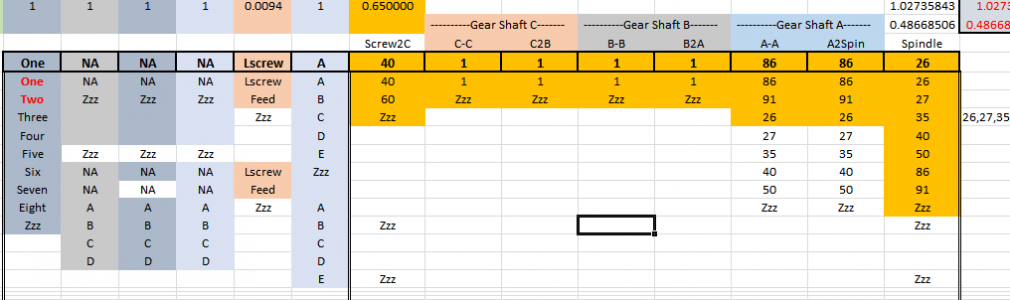

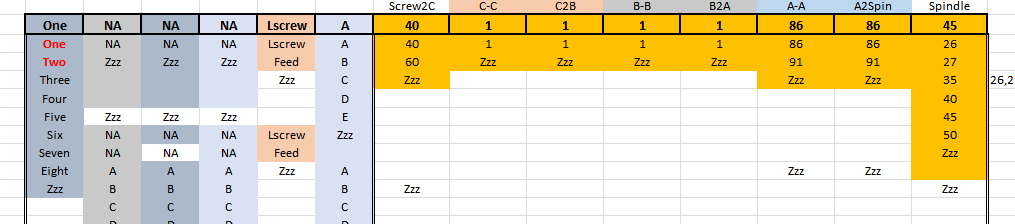

And if I understand your statements then you can have a the following arrangements of gears:

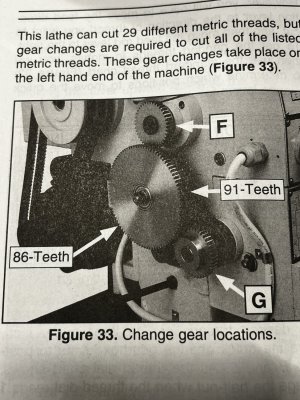

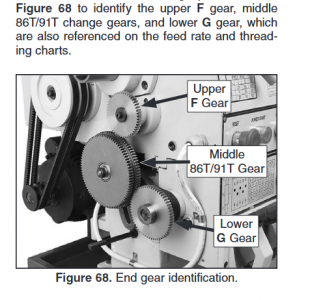

Gear box axle: 40T, 60T (two gears)

Spindle axle: 26, 27, 35, 40, 50, Missing 45. Plus the 86 and the 91 gears fit here also, but do they separate?

Exchange gear axle: 86, 96 Plus the 26, 27, 35, 40, 50, Missing 45 gears will fit on this axle.

I will run the gear arrangements show at the bottom for you. Please let me know if these conditions apply.