@keeena I was just writing the below message when yours came in. Please do test it out. I found it interesting that there was even a setting row (7) where you did not have to use the exchange gear. A-5 40T(gear box) 26T(spindle) and one gets almost the same results. 3.00182 pitch.

Good night.

Dave L.

Edit: Corrected lathe sheet G4003G and so changed the file and its name to: TPI_ManyLathesRev1 NB06_2023

--------------------

@keeena @TakeDeadAim

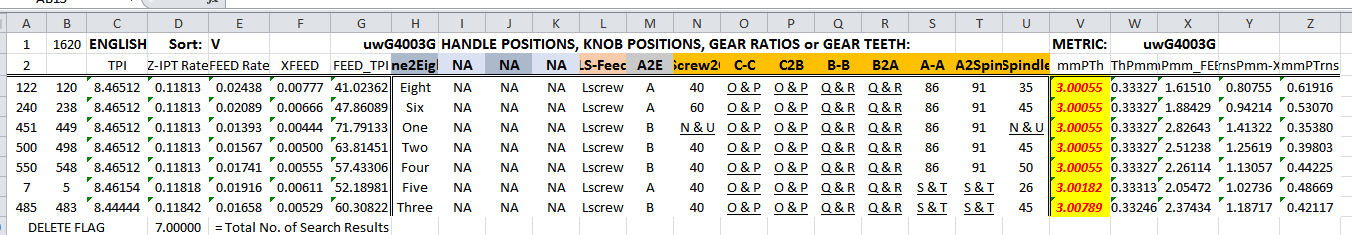

If you look at the table I posted above at you will see that you do not need the 45T to get the 3mm/T (3 pitch). There are other options.

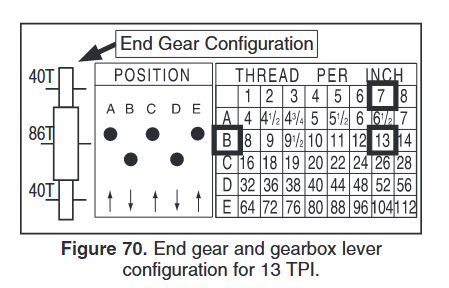

A-8, 40T(gear box)-86T\91T-35Tspindle) yields the same results , 3.00055 mm/T pitch. (91T in contact with the 35T)

or

B-4, 40T(gear box)-86T\91T-50T(spindle) yields the same results , 3.00055 mm/T pitch. (91T in contact with the 50T)

or

.... There are other options in the table as well.

One cannot get an exact 3.00 pitch, even with the 45T gear.

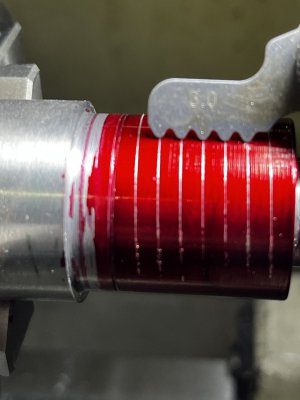

@keeena You can run these tests if you like to compare. But one cannot measure the difference between 3.00 exact and 3.00055mm/T. After all 0.0005mm very small, 1/2 a micron! This is why the manufacturers consider this to be accurate in their tables.

But it means nothing to me if you guys want to be shipping your gears around. I was just trying to help out. Yes, I should have picked up on the fact that you were talking about pitch and not TPI, but that first posting through me off and I was focused on making sure the spread sheet for the G4003G worked correctly.

If you down load it and run it with the macros you will have a listing/table of all 1620 thread values you can make. The workbook then lets you sort and search this listing to generate a list of the possible ways to make most standard threads. There are even features(macro) to hide the unused columns and of course to do searches. I went to all of the trouble to automate this for my lathe and then decided to extended it for other lathes just to help folks out on HM.

Dave L.