- Joined

- Sep 8, 2019

- Messages

- 4,392

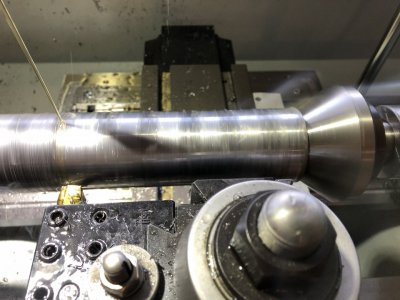

This is the only way that I can assure myself that the holes will match up perfectly!And , more burrs to deburr .I would just drill it separate without the " template ". You could spot drill it just above 1/2" so you wouldn't be raising those outside burrs also .