- Joined

- Apr 3, 2016

- Messages

- 43

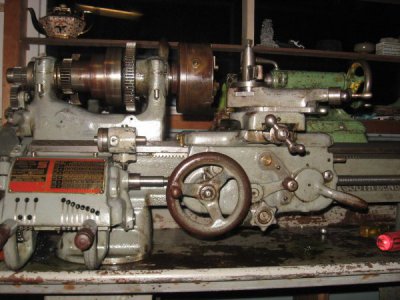

Hello all, my first here post on H-M. Here is the lathe I'm restoring. As purchased, and as it stood a couple days ago.

It was literally a basket case, all major components removed and in baskets or boxes. Luckily all the major components were there, and in reasonably good condition. The bed has been ground, but it appears to have been done correctly. Can't date it since the serial number is no longer visible. 30 days in to the restoration today. I can't (don't want to) even count the hours..... On the upside, I now know this machine inside and out to the last tiniest screw. I'm sure I'll have LOTS of questions.

It was literally a basket case, all major components removed and in baskets or boxes. Luckily all the major components were there, and in reasonably good condition. The bed has been ground, but it appears to have been done correctly. Can't date it since the serial number is no longer visible. 30 days in to the restoration today. I can't (don't want to) even count the hours..... On the upside, I now know this machine inside and out to the last tiniest screw. I'm sure I'll have LOTS of questions.

Last edited: