- Joined

- Mar 21, 2018

- Messages

- 1,606

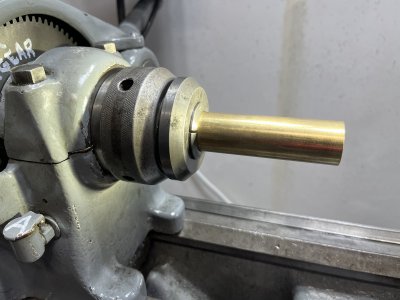

The surfaces for the thrust bearing need to be hardened, so you'll need both the inside and outside bearing washers.The three washers in the pic show where the 35mm ID thrust bearing will be, sandwiched between washers under the handwheel. I’m waiting for the thrust bearing to arrive but I think I only need one washer under the handwheel.

For your handwheel, chuck it up and get the outside polished to a near mirror surface. Your hand will be making contact with it while it is spinning and you don't want the wheel to "catch" on anything. Also, having spokes on your handwheel could catch a finger, so keep that in mind.