- Joined

- Dec 20, 2021

- Messages

- 890

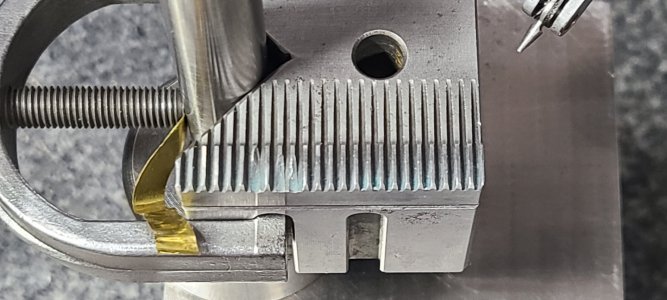

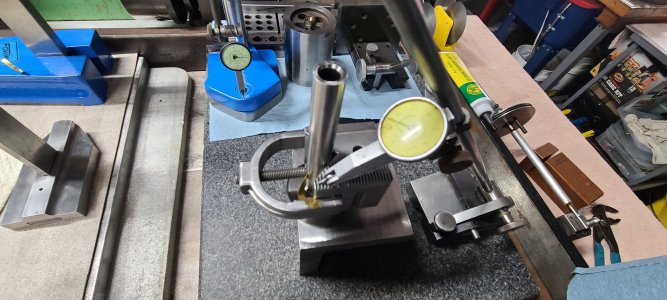

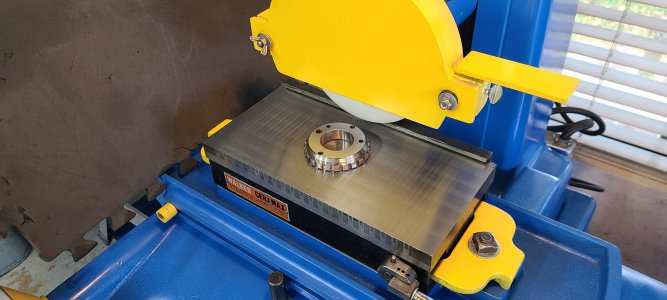

I did look quick, looks like the brand new ones are green. You probably have a real harig.Good point....I'm no expert and this is my first experience with one of these. The plate on top is a Harig plate. Pic attached.

It appears factory and of good quality but now...Hummmm?

Thanks for that...you just added another thin spot to my scalp..LOL

Thank you..

Thinking about this, it is possible there is a shim missing, or something similar somewhere? Maybe someone disassembled and didn't properly reassemble???