- Joined

- Feb 5, 2023

- Messages

- 19

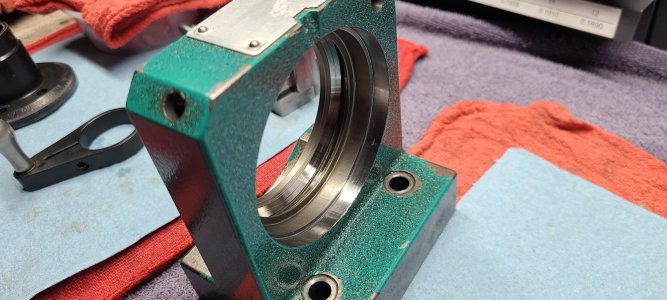

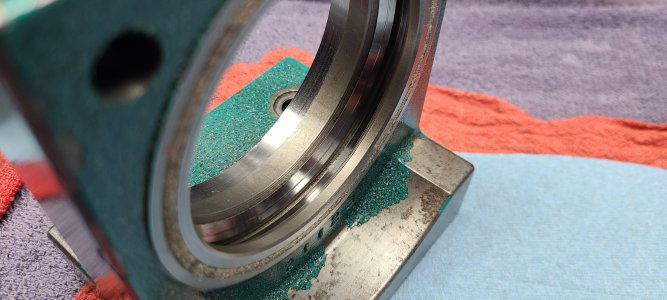

Greetings fellow hobbyists..First time posting and I thought I would start a question and answer session on a new project I'm working on. I just acquired a Harig Grind All #1. Upon inspection, I checked the runout and manually pressing on the V-block, I could get a movement of .005+..Not good. Also the fine adjustment screw for the V-block was missing and 3 teeth on the V-block for adjusting were broken. I have dissasembled, cleaned and inspected all the componets. Slight wear line on the center of the races from ball bearings. No physical or indicatable wear on the races..only slight visable bearing track line. I will attach a few pics of the project. Objective is to tighten this back to "reasonable" tolerances. Factory specs I hear is to within .0001 I will not be worrying about achieving that. Being I'm shooting in the dark here, I am looking for an option on tightening it up. My first notion is to grind the Back side of the bearing plate. The main housing has the races for the 32 bearings ground into the center of the body. No way to revive them. The front part which consists of the V-block is a 2 piece design. It is bolted from the back with (3) 10-32 screws which Sandwich it together on the bearings on the internal races. My thinking is if I grind the "back" half an undetermined amount, that will compress the bearings together to remove slop in them. Question is...How much? I was kicking idea around of starting with .0005, reasembling, testing it and working upwards from there. I can grind the rear portion easily but....it's going to be a feel it process. I would appreciate any suggestions. I have heard some people describe the races in these consisting of 2 washers ground and placed together to form a 90° for the bearings and that is what decides the preload. This has nothing like that. The 2 halves are "Tightened" together...No preload. Attached pics..

Attachments

-

20230206_185523.jpg495.9 KB · Views: 32

20230206_185523.jpg495.9 KB · Views: 32 -

20230206_185609.jpg645.6 KB · Views: 31

20230206_185609.jpg645.6 KB · Views: 31 -

20230206_185834.jpg689.2 KB · Views: 30

20230206_185834.jpg689.2 KB · Views: 30 -

20230206_185751.jpg498.6 KB · Views: 28

20230206_185751.jpg498.6 KB · Views: 28 -

20230206_185427.jpg467.6 KB · Views: 26

20230206_185427.jpg467.6 KB · Views: 26 -

20230206_185301.jpg477.8 KB · Views: 26

20230206_185301.jpg477.8 KB · Views: 26 -

20230206_193343.jpg274 KB · Views: 27

20230206_193343.jpg274 KB · Views: 27 -

20230206_191423.jpg412.6 KB · Views: 32

20230206_191423.jpg412.6 KB · Views: 32