Electrolysis is simple.

Battery charger and whatever iron or steel scrap for electrodes not stainless and some lye (what we use)

The electrodes will look like corn dogs to they need cleaning every few hours.

The lye will attack the paint to remove.

If you want high speed go to sams club and pick up a 3 pack of grill cleaner from grill department.

It is non aerosol pump type 3 quarts with sprayer for 9 bucks or so.

This is oven cleaner and it will get grease and paint in a hurry.

Do this OUTSIDE, spray on and let soak for 20 minutes then scrub with brush and rinse with water FROM A DISTANCE as this stuff burns and spray everything near as splatter will attack what it lands on.

A few cycles and you will be bare metal.

A night in the tank will get the surface rust.

As soon as it comes out dry the ways and wax them with paste wax to prevent rusting.

Tape then primer ASAP as it will rust fast.

Many coats of paint will fill the iron surface.

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

Thanks guys for the input..

TQ60 Thanks for play by play - electrolysis seems easy and super messy.. fun science, this project is my first attempt doing it.. I built a tank for the Lathe Bed and Supports last week and did allot of research & testing before dunking my Bed in.

I learned allot doing this first test run of just 12hrs , I was considering Easy off oven cleaner for the paint - I'm not in a big rush so I thought id give the electrolysis a try first.. It worked like a charm getting the paint off. I still have some rust to deal with.

The lathe bed came out pretty darn good for only being immersed for only 12 hours, there was some amount of rust removal but Id say 80 percent of the paint came off. I thought there would be some blackening of the metal but none was present.. there was no measurable difference in the bed ways that I could tell, Paint also came off where there was no anode nearby.. Bad Paint Job Maybe.

Washing soda (sodium carbonate, from supermarket or pottery supply) is usually used for the electrolyte rather than lye. If you do use lye it only takes a very small amount.

You'll need some serious amps to do a piece as big as a lathe bed; a small DC welder would be a good choice.

Rebar makes a good electrode, stainless electrodes give off chlorine which is nasty and toxic.

Mark S.

ps you may not like the finish this process gives- try a scrap piece first before you do the whole bed.

Mark I went every where looking for the Arm & Hammer Washing soda, Big box stores, Grocery Market - I ended up using Ph up from a pool Supply Store 100% Sodium Carbonate.

I tested both Rebar which was my first choice ( Inexpensive Vs Steel plate ) and Some 3/4 Steel Tubing as my anode, The difference was staggering between them.

wholly mackerel you hit the nail on the head with the power source Issue - unfortunately I learned that really fast after my chargers safety circuit cut in after only 3 minutes of use. I did some checking with my amp meter and found my charger was pushing 18 amps instead of 10 amps.. Worried that my bed was just sitting in water I removed an anode set from the Circuit and the amps dropped, I also checked to see if reducing the amount of sodium carbonate in the water would have the same effect, which it did.. I was using 1 ounce per a gallon when I started - doing a couple more test I found that starting a new mixture of 15 gallons of water with just 3 ounces of Sodium Carbonate did the trick in lowering the Amp draw to around 8.7 amps.

After a couple more hours I heard the dreaded click noise, I was like you have got to be kidding me - It was late so I removed an anode set from the circuit dropping the current to around a 5 amp load on the charger and let the bed cook over night...

In the morning I went to check on my Frankenstein creation... I found It lives which I think gives me the title of backyard scientist.

Note: I added an additional photo for comparison purposes.. I did a second bath for the lathe Bed only.

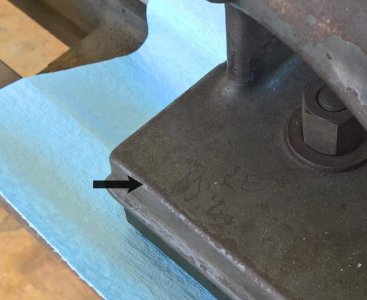

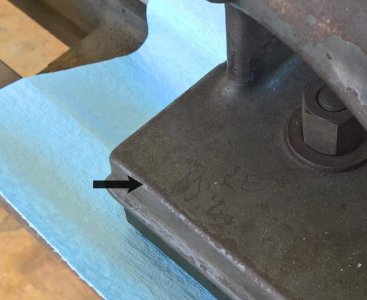

All paint and rust have been removed. The bed ways were cleaned with Ultra fine Scotch Bright pads and cutting oil.