Is that ammeter dc rated?

Most are only rated for dc but typical battery charger is not filtered so it may sort of work.

We may need to try the pool stuff someday.

We tried to find washing soda and given the data we had it was that or lye we use lye and pick it up at yard and estate sales.

You have discovered the concentrate alters the current as does the surface area.

We only use a couple electrodes in a 30 gallon trash can and rotate ends for longer items.

Our SB 14.5 bed was too long and heavy but nasty greasy so we just used the grill cleaner on it.

You did well with your first build.

We suggest going online to ebay and getting a SHUNT for the ammeter as it is very accurate and less worry about dropping an instrument in the tank.

They are basically a real low value high precision resistor that goes in circuit and give a multiplier output like 1 milli - volt per amp.

Measure voltage with a hf voltmeter and you are good.

We have car batteries for helping the dc power source as the current starts small then increases as the crud comes off but decreases when the corn dogs form.

Get a shunt and scrap panel meter or get an old school automotive direct reading ammeter and use it as it allows you to know when to clean the electrodes

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

Sup TQ..

No that Amp Meter is not DC compliant, No hall effect sensor.. But it works well with my 30 year old 12V Transformer Charger.

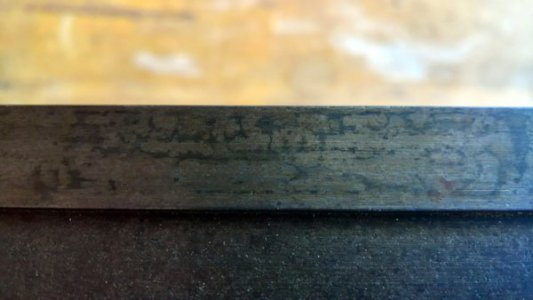

Charger is set to charge the battery at 2 Amps in first photo then 10 Amps second photo - Note This Meter will not work on new electronic charger...!

The Amp Meter may not be dead on accurate. But it told me exactly what I needed to know when I was doing the electrolysis and my chargers thermal protection cut in, which was will the amp draw lower if I lower the amount of Sodium Carbonate and or remove a bank of anodes, which it did.

Most people no little about Electricity or how it works - Its very cool you noticed and asked, this old style transformers battery charger doesn't output pure DC current like a battery does, so any amp meter will register.

And no the charger is not in contact with the lathe Bed

I could not find Arm & Hammer Washing Soda anywhere which is also 100% sodium Carbonate, So I Googled it and found many product contain 100% Sodium Carbonate.

LOL I have used Oven Cleaner to get paint off before, most notably my Ex-Girl friends name off my car door in High school, but I worried that it may damage the lathe.

I heard previously on wood working forums about using Electrolysis to remove rust, before this whole lathe thing started and when it was suggested to me on this forum it made sense to me.

Thank you for the first build complement, and your right I should be using a Shunt to check current. I'm a service Tech by trade with formal training in AC, Heating and electronics.

Thanks for all the Info, I bet Your South Bend Is amazing, and you can make really cool stuff.

personally I don't need a lathe but Ive always wanted one, I know ill never be even close to any of you guys in its use - but I can count so many time I've said to my self... if I only had a lathe I could fix that.. it was time to get one.

Nice talking to ya - Mike S