-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G4000 ELS Upgrade

- Thread starter Cletus

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,644

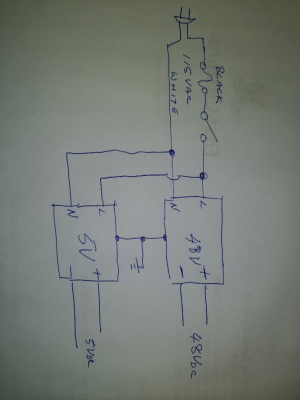

One thing that I did on my ELS build was to split the line voltage for the stepper power supply and the 5 volt supply. This allows me to disable the stepper and save wear and tear on the lead screw and gear box as well as the stepper power supply when I am not using power feed but still retain the tachometer function. Much of the simple lathe work that I do doesn't require power feed do I am probably only using it about 10 - 15% of the time.

Finally got all the electronics wired together, chip flashed, ready to go. Everything lit up like its supposed to but when i moved the encoder the servo did nothing. The flashing red light indicated position error. Went back and confirmed all of the wiring was in the right place. Same thing. hooked the driver up to the computer and tried to run the servo that way. Nada, showed position error. Dark clouds descended. In the midst of my depression I thought Id try to use the cable extension that came w the servo--previously was just attaching the serial plug directly from the servo to the driver. And that was the problem. I guess the pin out is different for the servo and driver. Everything seems to work OK now. One thing i did notice was if I gave the encoder a REALLY quick twist I would get a position error again. Is that normal? I guess ill put it on the lathe and see what happens. One question about your build--it looks like you have a number of grounds going to the case. The only ground i have going to case is the shielding from the encoder. the rest go to the ground on the 120V. Am I doing something wrong? Thanks for all the help!

- Joined

- Oct 24, 2013

- Messages

- 481

thanks again cletus. i think everything should be smooth sailing ahead. just waiting on pulleys and belts.Good going!

My case is plastic. All the grounds go to one central post and thence to ground at the electrical outlet.

I think you'll be fine.

@clough42 has an overspeed algorithm built into the software, that's probably kicking-in when you spool the encoder really fast.

thanks again cletus. i think everything should be smooth sailing ahead. just waiting on pulleys and belts.

Hey Cletus--back again bothering you for some knowledge--you mentioned that you had a crossfire plasma cutter. I have an opportunity to get a used crossfire pro for around 1700 bucks. I was looking through the langmuir boards and someone named Cletus said he was using a primeweld Cut 60. Is that you? Im trying to find a good plasma cutter that is not as expensive as the hypertherm.Good going!

My case is plastic. All the grounds go to one central post and thence to ground at the electrical outlet.

I think you'll be fine.

@clough42 has an overspeed algorithm built into the software, that's probably kicking-in when you spool the encoder really fast.

- Joined

- Oct 24, 2013

- Messages

- 481

Yes that's me. Just love my PrimeWeld CUT60. No issues with it at all. I have lots of posts on that forum with mods and tips for the Crossfire. Another great plasma cutter is Everlast. Hypertherm is of course the king of plasma cutters, though expensive.