- Joined

- Feb 23, 2016

- Messages

- 424

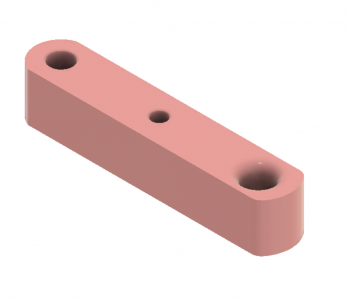

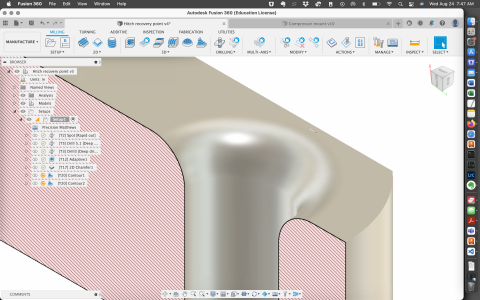

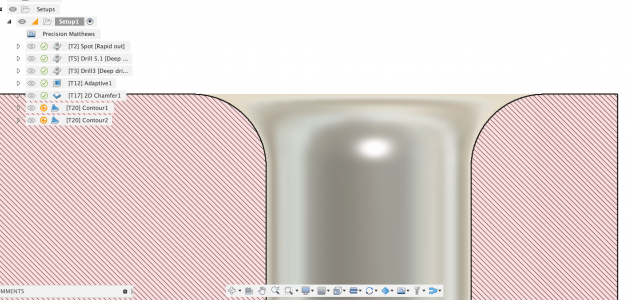

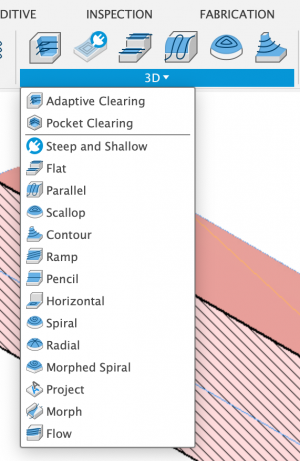

Ok I made a cut -- a simple bracket for a control box attachment, and used the sequence you recommended. This short video shows how much material is being removed by a 2-flute .25" mill, and ends with a Tormach SuperFly wreaking havoc: