F

f350ca

Forum Guest

Register Today

Thanks,Great looking work.

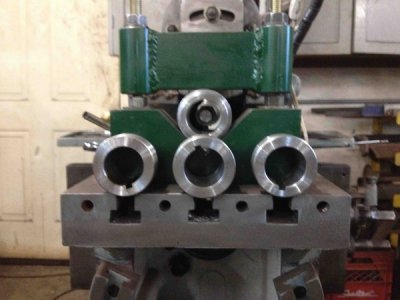

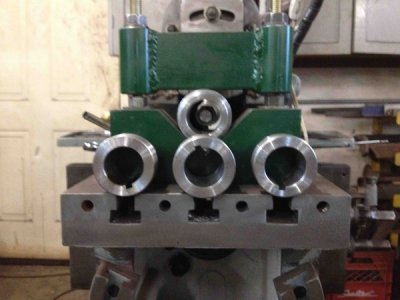

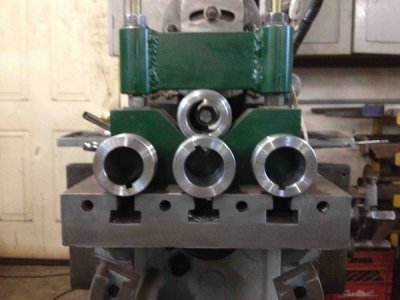

I have built a few splitters but never a processor. I believe I read a 3" cylinder with 10.5 tons of force for splitting? I can't see that being effective particularly if your gonna run a 6 or 8 way wedge? We run a 4" cylinder at 3000 psi and it struggled occasionally with the four way on difficult wood. Just my thoughts, you have obviously thought this out its evident by your nice work.

Its only going to have a single wedge, the wood I get varies a lot in size, some only needs a single split, some 6 or 8. The single wedge is slower but in the end I get wood the size I want. The splitter Im using now has a 3 inch cylinder but its fed off a single stage pump on the tractor at 1800 psi. It runs out of push from time to time, so Im hoping the two stage pump will give it the ump I need.

Greg