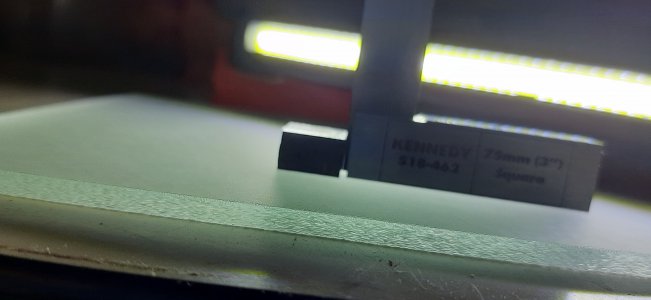

I enjoy filing but i forgot to get a fine file small file for this practice work so had to use sandpapers with a piece of steel that i filed flat and verified with a straight edgeIf you hate to file things, like I do, you might look for a die filer. I found a Butterfly filer awhile ago and man, that is a great tool. I found a machine file collection on eBay of 17 files, various shapes and coarseness, at about $10 per file. I can also use a cutoff hacksaw blade for a metal bandsaw substitute. It’s easy to do very precise work because you can see the file and a scribe line at the same time, and the file stays completely perpendicular to the table.

It’s turned around my whole poor attitude toward filing, maybe not completely 180 degrees, but at least 160 degrees.

Last edited: