Got a little shop time yesterday and today! First was the anvil tool for riveting. This is just a hunk of steel with a reamed hole to hold a piece of hardened drill rod:

The cutout is so it can reach into the steam dome. Plans called for 3/4"x2" BUT I couldn't get anything but 5/8". I figured that was close enough, particularly because I'm clamping it in a 5 ton vise

Next I started on the rivet tools. The way this works is there is 1 on the anvil that holds the rivet head, and 3 tools that you hit with a hammer to progressively shape the other side.

I cut the pieces to length. I saw someone else do the grooves to tell between the three tools, so I copied! I also tried a knurl but this material (W1) wasn't having it.

For the rivet head and tool #3, you need a 7/64" radius. I figured I'd try this in the lathe with a ground tool:

Sadly, I had pretty bad luck, ruined the tool, and messed up the stock! So I spent the $10 and ordered a ball endmill so I can do this on the mill

Today I got a 10-32 tap/die set in, so I made the stay rods and nuts, which go inside the boiler for one reason or another. The rods are bronze and were just threading on both ends after turning to size.

The nuts came out of some hex brass stock, which worked... FINE. They are a little tiny for my lathe, so I found myself needing to waste a bunch of material on the 4th instead of being able to part it off.

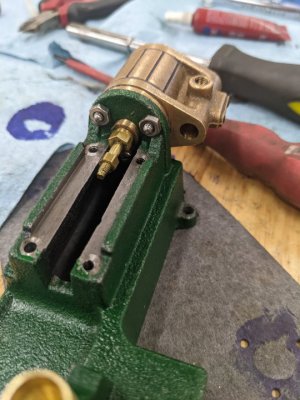

Additionally, my 3rd water pump casting showed up. I did the bottom, mount holes, pivot hole, and started the main set of holes from the top. I have an endmill coming to make the square bottom hole I need for this part a little easier, so I'll continue tomorrow.

Then today, I spent a while proving I watch too much Kieth Appleton. I made up some #5-40 fake stud bolts:

Then today, I spent a while proving I watch too much Kieth Appleton. I made up some #5-40 fake stud bolts:

My crankshaft is pretty bad (when I used it to turn the flywheel, it spun and tore it up with a set screw), so unfortunately I have to wait for a replacement.

My crankshaft is pretty bad (when I used it to turn the flywheel, it spun and tore it up with a set screw), so unfortunately I have to wait for a replacement.