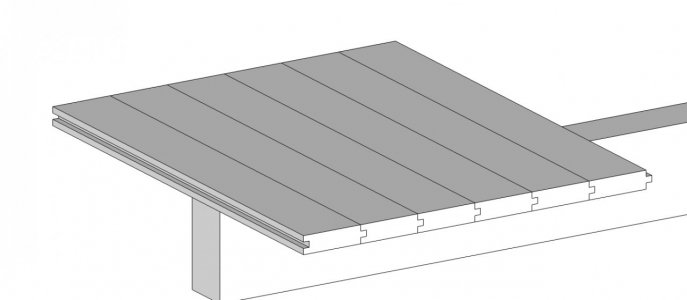

My house has a rather unique type of construction for the ceilings and roof. There are 4x8 beams 4' on center over the bedrooms, hall and the bathroom. On top of these beams are 2x6 tongue and groove boards that are the ceiling for the bedrooms, hall and bath and the floor of the loft. There are no ceiling joists as in a typical house. The roof is similar with 2x6 T&G boards resting on 4x8 beams. No roof rafters.

View attachment 392130

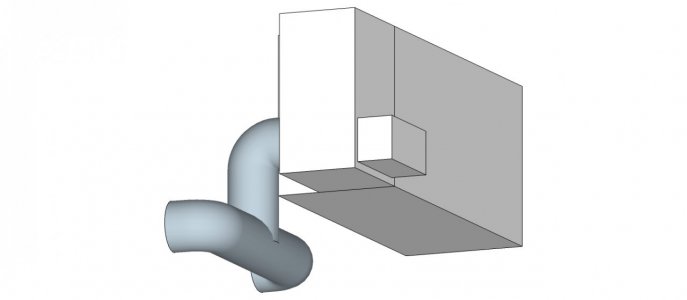

There is no attic to run ducting in. There is a centrally located hall closet and an adjacent alcove in the living room that you could run ducting in. You can only reach the living room/kitchen, one bedroom and the hall with ducting. This is the shape of the ducting.

View attachment 392136

There is a plenum off the furnace with a 6x12 duct on one side that goes to the living room/kitchen and a round 7" duct on the other side of the plenum that goes to a bedroom and the hall. I used a ducting calculator to determine the size of the ducts. One corner of the loft would be used for the furnace. The return air has several options and is not shown. The tubing for the ac would run along the side of the loft to the back of the house where the evaporator would be.

I have considered a mini split. They are beyond ugly. No attic/ceiling to hide a point of use outlet. I am stuck with either ugly boxes hanging on the wall or a small central heat/ac furnace that only reaches the main rooms in the house.