- Joined

- Feb 2, 2014

- Messages

- 1,068

The plans are not very specific as far as the governor goes and does not explain how everything has to work together. I have found that when working with a set of plans they are more of a suggestion than a rule as to how to make it.

These are the four parts of my simple carburetor less the spring. I have used this design on four of my other models and they work fine.

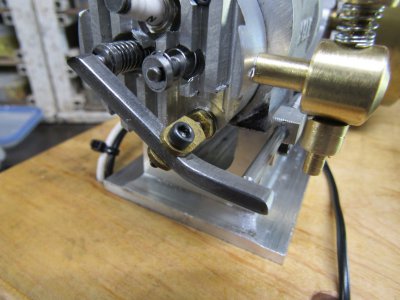

And the carb assembled and installed on the engine.

I couldn't help myself since we are so close I just had to give it a try.

I taped a gas tank I had made for another engine onto the side of the box and installed a short hose to the carb. Put in some fuel and gave it a few spins.

I started to get some talking (firing) from the engine as I was adjusting the carb and timing. It even made a few sentences of 5 to 10 seconds long and I thought I was almost there but then for no apparent reason there was no compression. Tomorrow I will take the head off and see what is going on.

YES IT DOES RUN just not for very long.

Thanks for looking

Ray

These are the four parts of my simple carburetor less the spring. I have used this design on four of my other models and they work fine.

And the carb assembled and installed on the engine.

I couldn't help myself since we are so close I just had to give it a try.

I taped a gas tank I had made for another engine onto the side of the box and installed a short hose to the carb. Put in some fuel and gave it a few spins.

I started to get some talking (firing) from the engine as I was adjusting the carb and timing. It even made a few sentences of 5 to 10 seconds long and I thought I was almost there but then for no apparent reason there was no compression. Tomorrow I will take the head off and see what is going on.

YES IT DOES RUN just not for very long.

Thanks for looking

Ray