Hi Brino. The Proxxon press that I have looked at has a max speed of 4500rpm and is 300$ more expensive than the best one at a hardware store here. I know about 'you get what you pay for'. But I really don;t want to spend that much.Hi @GazzaS

I have heard great things about the Proxxon sensitive drill presses; but have never used one myself.

I did see one used, but wasn't sure that I'd use it enough to justify it.

Welcome to the group!

-brino

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Press and drill bit question.

- Thread starter GazzaS

- Start date

I added the imperial measurement from a converter online. Perhaps I made a mistake. I left the metric measurements to provide comparison.do you mean .0181" ? .181" is close to 3/16" which is not overly fragile. If so what you should be looking for is a high speed sensitive drill.

You did nice work, there! I have a Dremel but I don't have steady hands. I have a Dremel drill press, bit it has too many plastic parts and isn't rigid enough for accurate work.A few years ago I wanted to drill small (0.032”) holes into stainless tube. This was before I had machine tools, but I’m not sure my approach would be different. The bit was so small that my drill press was not useful (too slow and not enough feel). I used a Dremel with its little 3-jaw chuck. My tube was thick enough (0.035” wall) that I made some transverse slices to thin where I drilled, as shown below. The bit noticeably degraded but made it through the six holes I wanted.

I’m not sure how helpful it is to your example, but I’d want a pretty fast spindle (5-8k for the 0.032” drill I used) and something with feel. I know there are “sensitive drill presses” that seem well suited to it. My current drill press will go to 4K rpm, but I don’t think there’s enough feel to avoid breaking a bit.

This is an “atomizer” that goes across the nozzle of a backpack leaf blower and lets me dispense insecticide as a mist; for mosquitoes.

Dave,Gary,

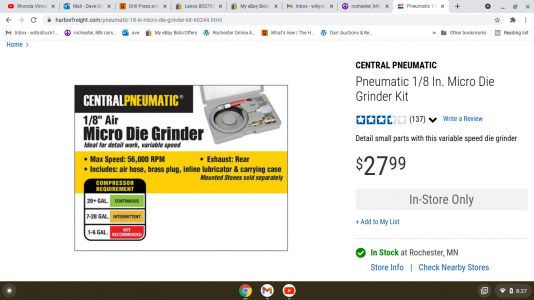

best to get an air micro pencil type die grinder, which HF offers for $20-$30 for a kit. it can run speeds up to 65k rpm and can handle the tiny bits. then just make a small press to hold it firm and rigid and make a controled precise feed. doesn't have to be fancy, just solid. Dave *note you can also use all the tiny diamond grit shapes for starting tiny holes with this grinder.

I've never heard of one of those before. I'll look into it. Not sure about making a press, though.

That is a great looking (and working) home made drill press.The 0000 and 00000 center drills are fragile too. Unless your drill press has zero runout. The tip of the drill will start the hole but when you reach the chamfer, the runout and relative stiffness of the shank will take over and snap the tip. I drilled sub-millimeter holes for forty years with a small drill press that I made from a small motor and a frame made up in the form of a parallelogram. Although the drill tip swings through an arc, if the frame is set horizontal at mid depth, the deflection for a .25" deep hole is less than .0002".

This drill press has drilled tens of thousands of holes, mostly in fiberglass pc board and still occupies a place on my workbench.View attachment 372411

I'm so new at this and had to look up runout. It's something I never thought of before as I'd expect something made to do accurate work, like a drill press, would have inaccuracies inside that made doing accurate work less possible.

- Joined

- Oct 14, 2013

- Messages

- 984

You may also.want to.make a jig to get your holes centered on the tube.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

- Joined

- Mar 10, 2013

- Messages

- 1,428

Gary,Dave,

I've never heard of one of those before. I'll look into it. Not sure about making a press, though.

the body of drill is only 5/8 inch, so if you just make a simple small bracket and you can mount it to your small drill press spindle depth bracket and use your current press for a feed and the micro drill is adjustible up to 56k rpms. you can make a small flange bushing in the depth stop to keep it more stable and accurate without side play.

Dave

Attachments

Dave,Gary,

the body of drill is only 5/8 inch, so if you just make a simple small bracket and you can mount it to your small drill press spindle depth bracket and use your current press for a feed and the micro drill is adjustible up to 56k rpms. you can make a small flange bushing in the depth stop to keep it more stable and accurate without side play.

Dave

Thank you for the thoughtful advice. It may be a bit beyond me as I really have nothing to work with except a hand drill and some woodworking equipment. But I will see what I can find at my local hardware shop. I have to start somewhere.

It would be fairly easy to set this up with woodworking tools. For a Dremel or a pneumatic drill, you could set it up horizontally. Set the drill body up in a sliding wood block with wood guides that are 90° to a fence. Take a 2nd rip of lumber and use the drill to mark the centerline height, rip a V down the length wide enough for the tubing. Line up the V with the drill bit and attach it to the fence. Wax everything up and hand feed the drill back and forth to drill the holes.

- Joined

- Jan 20, 2018

- Messages

- 5,629

As others have stated, what you are looking for is called a Sensitive Drill Press. They are capable of the speed, control and delicate feed that are needed for drills that small. They are not cheap, but nothing in this field is.

www.globalindustrial.com

www.globalindustrial.com

Dumore 8576-210 Sensitive Drill Press, Series 16, 1/16 HP Universal, 15,500 / 18,700 RPM

Dumore 8576-210 Sensitive Drill Press, Series 16, 1/16 HP Universal, 15,500 / 18,700 RPM. Buy it and Save at GlobalIndustrial.com