-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Draw bar issues on PM833TV

- Thread starter LVLAaron

- Start date

Here's another good design if you don't want to mess with the air cylinder. This adds an extra rod that de-couples the handle from the butterfly valve. That way when you pull down on the slide you aren't putting a lot of force on the butterfly valve handle.

I'm planning to make this style for my 833tv as I prefer a simpler mechanism.

I'm planning to make this style for my 833tv as I prefer a simpler mechanism.

So it seems that we are all experience the same stickiness in the R8 collets on the PM833T.Mine does the same. I keep a small, plastic deadblow by the mill for that purpose.

- Is this kind of stickiness normal on the BP knee type milling machines?

- Is this an isolated issue because of how the R8 quill in the PM833T or PM833TV is built?

@David - the design that you linked to is similar to what I was working on. I have it all figured out on how to use existing cover screws etc. He added a pneumatic actuator to push down the drawbar and maybe this is what makes the difference.

I think that resolving this issue and coming up with a PDB design that actually works reliably on the PM833T is what this group can help with.

Ariel

- Joined

- Dec 26, 2015

- Messages

- 2,079

None of this is unique to the 833. R8 collets in my RF-45 needed a tap on the top of the drawbar once it was manually unscrewed. So did my 935 until I added the PDB. Most PDB's have some means of pushing down on the drawbar cap nut while the impact wrench hammers away. If the drawbar is given sufficient downward pressure while simultaneously being unscrewed, it will force the collet downward and it will drop free. If you don't push down on the drawbar while unscrewing it, the collet will remain in a wedged position as the drawbar moves upward during the unscrewing action.So it seems that we are all experience the same stickiness in the R8 collets on the PM833T.

The reason that I put on hold my PDB built is that I am not convinced that it will release the R8 collet. I tried the butterfly pneumatic wrench by activating it and pushing it down by hand but it did not release the collet, it still needed a tap by a mallet. Maybe it needs to be mounted rigidly to the mill to actually release the collet.

- Is this kind of stickiness normal on the BP knee type milling machines?

- Is this an isolated issue because of how the R8 quill in the PM833T or PM833TV is built?

@David - the design that you linked to is similar to what I was working on. I have it all figured out on how to use existing cover screws etc. He added a pneumatic actuator to push down the drawbar and maybe this is what makes the difference.

I think that resolving this issue and coming up with a PDB design that actually works reliably on the PM833T is what this group can help with.

Ariel

I have seen PDB designs that required the operator to pull down against the drawbar cap nut while articulating the impact driver. This is one example of that type of design. And there are others (such as the Maxi Torque-Rite and Kurt) that have a pneumatic actuator pressing down on the drawbar during the operation.

Is the quill down movement needs to be locked while doing this? With a tap from a mallet there is no need to lock the quill. This might be why just pushing down on the pneumatic butterfly wrench was not enough.None of this is unique to the 833. R8 collets in my RF-45 needed a tap on the top of the drawbar once it was manually unscrewed. So did my 935 until I added the PDB. Most PDB's have some means of pushing down on the drawbar cap nut while the impact wrench hammers away. If the drawbar is given sufficient downward pressure while simultaneously being unscrewed, it will force the collet downward and it will drop free. If you don't push down on the drawbar while unscrewing it, the collet will remain in a wedged position as the drawbar moves upward during the unscrewing action.

I have seen PDB designs that required the operator to pull down against the drawbar cap nut while articulating the impact driver. This is one example of that type of design. And there are others (such as the Maxi Torque-Rite and Kurt) that have a pneumatic actuator pressing down on the drawbar during the operation.

- Joined

- Dec 26, 2015

- Messages

- 2,079

Here's an example of a DIY PDB that has a pneumatic actuator that pushes down on the drawbar during operation (part 4 of 4).

- Joined

- Dec 26, 2015

- Messages

- 2,079

I do NOT have to hold or lock the quill travel during PDB operation.Is the quill down movement needs to be locked while doing this? With a tap from a mallet there is no need to lock the quill. This might be why just pushing down on the pneumatic butterfly wrench was not enough.

- Joined

- Dec 26, 2015

- Messages

- 2,079

Have you removed or checked the interference for the dog-point set screw that meshes with the slot in the side of the R8 collets? I removed mine completely. But if that set screw is in too far, or has a point that's too wide, it will contribute to the "stickiness" of the R8 not dropping free.

- Joined

- Oct 28, 2020

- Messages

- 528

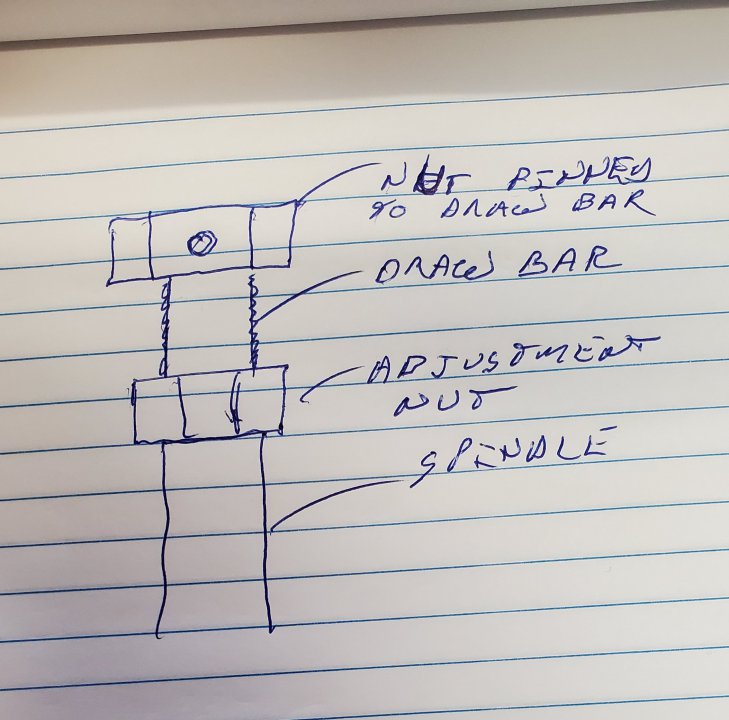

The draw bar on my wrong-fu 45 has two nuts, one sits on the top of the spindle and one is fixed (pinned) to the top of the draw bar. So you just use two wrenches to tighten/loosen, no worries about trying to lock the spindle.