- Joined

- Oct 4, 2020

- Messages

- 484

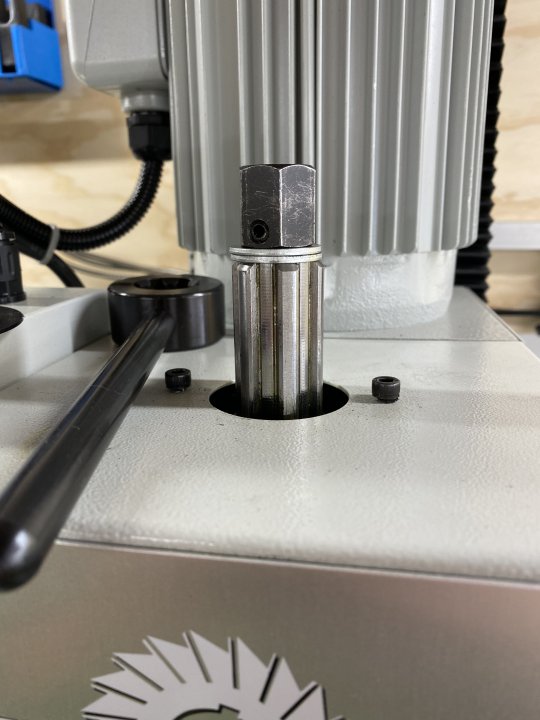

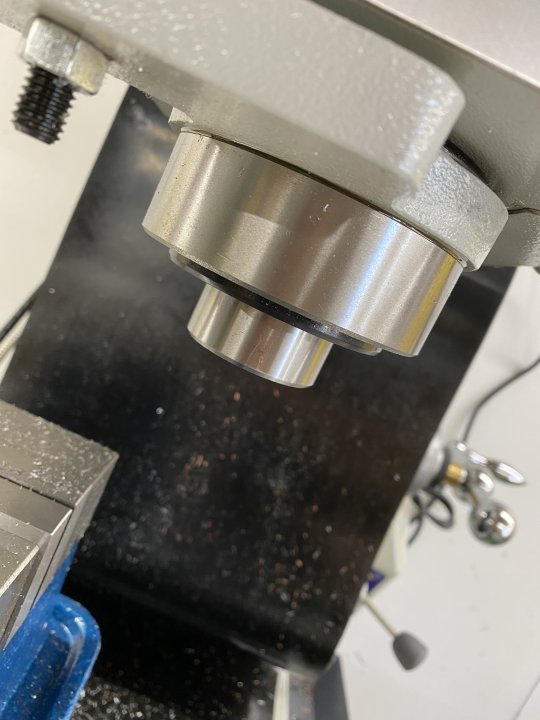

My 833TV doesn't have flats on the spindle. So tightening the draw bar is a complicated matter. I do have the black wrench to keep the shaft from spinning, but it only slides over the draw bar if the draw bar is is in the exact right spot - and can't be used at all with my fancy shims in there. The shims are less of a problem, I can make smaller ones... but the overall problem / question remains. What do?