-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY OD Grinder fixture, For the surface grinder- maybe

- Thread starter Janderso

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,319

It lowers the ability to slip. The paper adds a little bite (friction). metal to metal sometimes has the slide potential. Nice idea Jeff.

- Joined

- Oct 16, 2019

- Messages

- 6,580

It lowers the ability to slip. The paper adds a little bite (friction). metal to metal sometimes has the slide potential. Nice idea Jeff.

That makes sense. Like putting plywood on a pallet jack before setting a machine on it.

- Joined

- Jan 31, 2016

- Messages

- 11,471

Much more bettery !Dave,

Is this better?

- Joined

- Mar 26, 2018

- Messages

- 8,408

What he said....It lowers the ability to slip. The paper adds a little bite (friction). metal to metal sometimes has the slide potential. Nice idea Jeff.

You learn these things a long the way.

- Joined

- Mar 26, 2018

- Messages

- 8,408

I’m going to bore it.I like that setup a lot more than the expanding arbor. Using a boring head or a key seat cutter?

Stay tuned for my design. Don’t point and giggle when you see it. Be gentle.

I’m going to bore it.

Stay tuned for my design. Don’t point and giggle when you see it. Be gentle.

Oh I didn’t look closely enough. I thought you were making an ID groove, so you might use a rotary table with a key seat cutter or a single point cutter in the boring head. With the piece fixed on the mill table, I guess you can bore and press in an insert to leave a glove gap?

- Joined

- Mar 26, 2018

- Messages

- 8,408

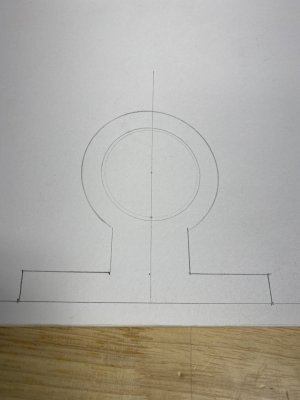

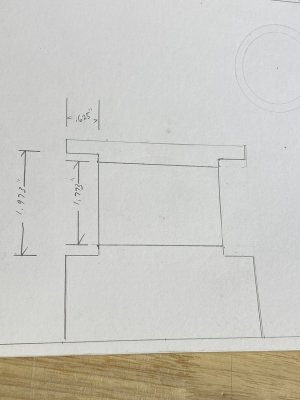

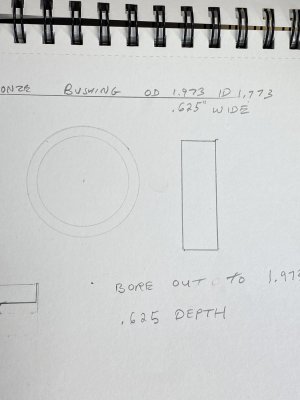

This is not adequate but this is what I have. I don’t do anything like cad or fusion etc.

I’m still not sure what to do about the oring or sealing method.

I did notice there is a groove in the spindle. I can make it work but I can’t visualize it until I cut the bore fir the bushings.

Then I can put it together, figure out my next move before I machine the brass.

I will have a method to add lubrication and it will be shielded from grit.

One step at a time.

The bushing will be .625 wide and .200” thick. I am going to allow .001” clearance between the spindle and the bushings. As it is now there is probably.005”. Way too much!

I do have the bore coplanar with the base and both ends standing on the surface plate are within .001”. In other words, I’ve been careful with each step. I’m really trying to not screw it up.

I’m still not sure what to do about the oring or sealing method.

I did notice there is a groove in the spindle. I can make it work but I can’t visualize it until I cut the bore fir the bushings.

Then I can put it together, figure out my next move before I machine the brass.

I will have a method to add lubrication and it will be shielded from grit.

One step at a time.

The bushing will be .625 wide and .200” thick. I am going to allow .001” clearance between the spindle and the bushings. As it is now there is probably.005”. Way too much!

I do have the bore coplanar with the base and both ends standing on the surface plate are within .001”. In other words, I’ve been careful with each step. I’m really trying to not screw it up.

Attachments

-

B59C16D6-A052-43DA-B070-6CF595F5C9DB.jpeg171.5 KB · Views: 11

B59C16D6-A052-43DA-B070-6CF595F5C9DB.jpeg171.5 KB · Views: 11 -

DBF646B8-5A2A-4ABD-B648-57DD8D912C3E.jpeg207.7 KB · Views: 9

DBF646B8-5A2A-4ABD-B648-57DD8D912C3E.jpeg207.7 KB · Views: 9 -

04450BED-B7F9-4871-A2F0-1F211136CD8D.jpeg200.2 KB · Views: 9

04450BED-B7F9-4871-A2F0-1F211136CD8D.jpeg200.2 KB · Views: 9 -

B6371EA6-0A5B-4974-9163-AE7BDBB701E4.jpeg208.3 KB · Views: 10

B6371EA6-0A5B-4974-9163-AE7BDBB701E4.jpeg208.3 KB · Views: 10 -

40DEEDF3-E487-4E13-BCF5-35B32F48A383.jpeg621.7 KB · Views: 10

40DEEDF3-E487-4E13-BCF5-35B32F48A383.jpeg621.7 KB · Views: 10

- Joined

- Mar 26, 2018

- Messages

- 8,408