-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Belt Grinder Build Questions

- Thread starter devils4ever

- Start date

-

- Tags

- belt grinder

- Joined

- May 13, 2019

- Messages

- 1,016

I got my motor, VFD, and wheels ordered. I'm still designing this in FreeCAD, but it's close to completion.

For reference:

Motor: Dayton 36VF69 from Grainger. (Detail: 2 HP, 3-phase, 3480 RPMs, 56C frame, TEFC, Inverter rated, UL, ball bearings, 5/8" shaft)

VFD: KBAC-29 (1P) 10001, rated to 3 HP at 220VAC 1 phase input

Wheels: Belt Grinder 2x72 Wheel Set knife Grinder 6" Drive 5/8" Bore 4" Track 2" Idler from grinder-pro on eBay

I'm trying to determine how much force is needed on the tracking wheel. Is it 10 lb, 20 lb, 30 lb, 40 lb, or more? I plan on using a gas spring unless that are better alternatives.

For reference:

Motor: Dayton 36VF69 from Grainger. (Detail: 2 HP, 3-phase, 3480 RPMs, 56C frame, TEFC, Inverter rated, UL, ball bearings, 5/8" shaft)

VFD: KBAC-29 (1P) 10001, rated to 3 HP at 220VAC 1 phase input

Wheels: Belt Grinder 2x72 Wheel Set knife Grinder 6" Drive 5/8" Bore 4" Track 2" Idler from grinder-pro on eBay

I'm trying to determine how much force is needed on the tracking wheel. Is it 10 lb, 20 lb, 30 lb, 40 lb, or more? I plan on using a gas spring unless that are better alternatives.

- Joined

- May 13, 2019

- Messages

- 1,016

The design that uses nested tubes and a wire spring calls for 30lb. I would guess a similar amount of force would be good for a gas spring using the lever arm design.

Nested tubes? Could you elaborate?

- Joined

- Mar 25, 2013

- Messages

- 4,617

Mine probably has about 10lb force on the arm. I just used a regular spring. See what other answers you get.

Robert

Edit: should clarify. My pulley probably has about 10 lbs of force. The spring is under more tension because of the geometry.

R

Robert

Edit: should clarify. My pulley probably has about 10 lbs of force. The spring is under more tension because of the geometry.

R

- Joined

- Jul 17, 2020

- Messages

- 323

Nested tubes? Could you elaborate?

The common "simple" design. Rather than the pivot arm like the photo @Masterjuggler posted, it's like a trailer hitch with a vertical post that the post holding the tracking wheel fits into, with a coil spring at the bottom. It works, but there is a bit of wobble in the post due to the fit between the square tubes. When I take the time to work on mine, I intend to move to a pivot setup as it does mess with the belt tracking a little. I use a wedge in there to keep it from moving about right now. I like the one @Masterjuggler did with different mounting points. That is a nice idea to adjust for various needs while still being a pretty simple to build design.

BG-272 DIY 2 x 72" Belt Grinder

DIY 2" x 72" Belt Grinder Project Like almost every newbie knifemaker owning a decent belt grinder is dream. When I realized the price of...

- Joined

- May 13, 2019

- Messages

- 1,016

Okay, I think I got it. Thanks.

I'm assuming a gas spring offers dampening of the motion. Is that correct? A simple spring is a lot cheaper!

I'm assuming a gas spring offers dampening of the motion. Is that correct? A simple spring is a lot cheaper!

- Joined

- Jul 17, 2020

- Messages

- 323

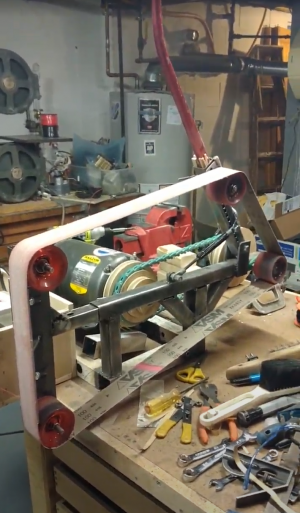

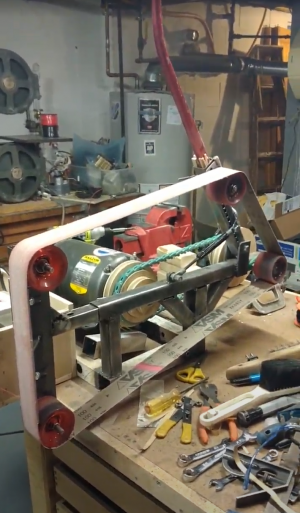

The one I did is EXCEEDINGLY jank lol. It's thin wall tubing welded together with some microwave transformers with rewound secondary coils, which is why it looks like bird poo and has holes blown through it. To keep the arm from wobbling, I cut some washers out of a soda bottle. I had intended to weld a proper handle to the arm, but was too excited to use it and instead jammed the left side of a bicycle front fork into it, and never changed it because it's quite comfortable.

I like a gas spring because it's damped and doesn't shoot off if the belt breaks. I believe it's also more linear than a coil spring. Here is the exact one I got, it's not very expensive: https://www.mcmaster.com/9416K11/

This photo is from a while ago, it's since moved to its own spot on a different bench.

I like a gas spring because it's damped and doesn't shoot off if the belt breaks. I believe it's also more linear than a coil spring. Here is the exact one I got, it's not very expensive: https://www.mcmaster.com/9416K11/

This photo is from a while ago, it's since moved to its own spot on a different bench.

- Joined

- May 13, 2019

- Messages

- 1,016

Thanks, but which one do you have? They list 15, 20, 30, 40, 50, 60, 70, 80 lbs extension force versions. I'm a little confused. They list extension force, but you really want compression force, don't you? You have to click on each to to find this out.