Hi Paddy,

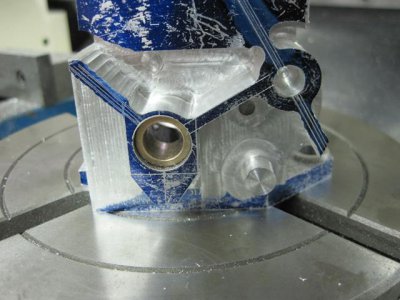

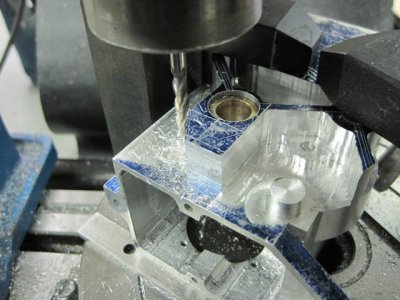

The original flywheel was basically pot-metal but does have some weight to it. I agree the brass is probably disproportionally heavy but better too heavy than too light. Each of the 32 fins had to be cut to a depth of .500" with a 1/8" end mill which took multiple passes on my small Sherline mill and brass is much easier to machine from that standpoint. Aluminum would have machined almost as well perhaps but doubt if it would be heavy enough, steel would have had the weight but more difficult to machine as required. Actually, though I haven't weighted it yet, I suspect the final model will weigh almost 3/4 as much as the original. Things like the gas tank have much thicker walls than the stamped original, and so on, even though the original engine block was cast iron where as mine is aluminum. Fortunately, my intent was only to scale the look and detail of the original and not its weight. Its gonna be a heavy little thing no doubt. By the way, the cover is a rapid prototype (3D printer) version. Not sure how I am going to make the final version yet, possibly even machine it from a billet of aluminum but that remains to be determined. In the meantime the RP part suffices.

Bill