-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cromwell S800 Mk3 lathe

- Thread starter RodF

- Start date

- Joined

- Apr 16, 2014

- Messages

- 142

Cut a piece of gauge plate for the gib. Made a fixture to hold the plate while I milled the angle. It turned out too thick so milled it down in thickness. Put some blue on to mark the adjustment screw positions and used a bull nose cutter to make the dimples. I will make some new adjustment screws at some point as one is lost anyway. You can still see the engine turning on the side of the top slide.

Last edited:

- Joined

- Apr 16, 2014

- Messages

- 142

The last major part to make is the cross slide drive shaft. This is a 30" long 5/8" diameter shaft with a slot cut in it for most of its length. On my mill the slot needed to be cut in 3 operations.V blocks and clamps allowed for repositioning without losing registration. I need to get the lathe up and running now to machine the shoulder of the shaft to fit into the driver. First I will need to machine the chuck adapter to fit my 4 jaw chuck. So getting the lathe running will be my main focus now.

Last edited:

- Joined

- Apr 16, 2014

- Messages

- 142

Worked on getting the lathe assembled today. No major problems. The worst thing so far is the amount of wear on the cross slide ACME thread and its nut, not a huge problem as backlash is not a big issue there. Cut my first chips on it, modifying the chuck adapter plate for the 4 jaw chuck. The adapter plate is cast iron and somewhat hardened so it is quite hard work. Managed to get the belt slipping so will need to add weight to the motor so I can get more tension on the belt. Still plenty to be done.

Last edited:

- Joined

- Apr 16, 2014

- Messages

- 142

- Joined

- Apr 16, 2014

- Messages

- 142

Have started making things on the lathe . However still plenty to do. I need to replace the top slide lead screw and nut. The screw is well worn and there is lots of play in it. Have ordered a 3/8" ACME tap for the nut and will make the thread on the lathe. Have also ordered a set of imperial taper pin reamers to redo all the slider drive handle retaining taper pins.

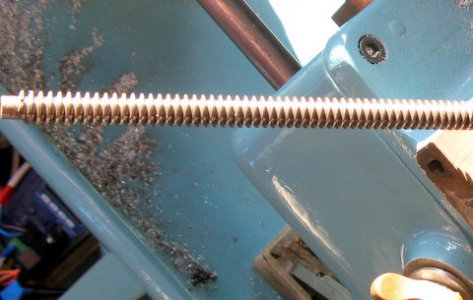

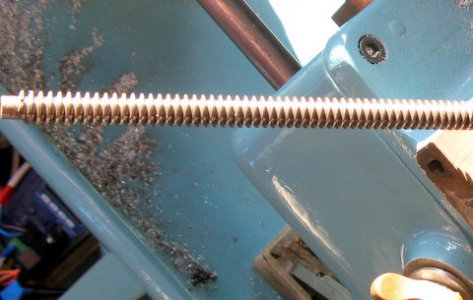

Worn top slide ACME thread

Worn top slide ACME thread

Last edited:

- Joined

- Apr 16, 2014

- Messages

- 142

Undercoated the last few parts. The steady's and the back gear mounting arms. The travelling steady is a beautiful bronze casting and I will be using it soon to make a new cross slide ACME thread. Unfortunately ordered a right hand 3/8" ACME tap for the cross slide nut before realising it was a left hand thread. However will probably use it for a Z axis drive on a CNC router.

- Joined

- Feb 17, 2013

- Messages

- 314

Hi Rod,

Your Cromwell is coming along beautifully. Nice job on the cleanup and paint job.

Michael

Your Cromwell is coming along beautifully. Nice job on the cleanup and paint job.

Michael