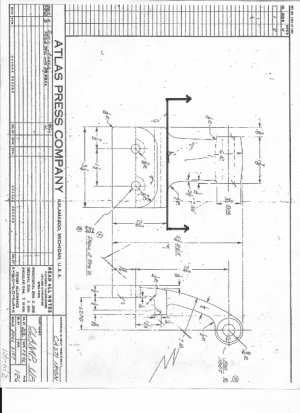

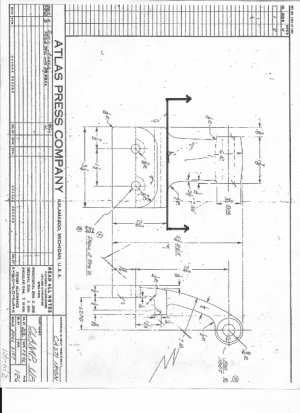

Now that I have the two easier taper attachment clamp parts I decided to start looking at the upper clamp - a bit more complex. This is the drawing for the part in question - I added a dividing point where it makes sense to me to make two parts and then join them

Then I found this laying around the scrap pile

The arm is a bit long and the hole is oversized but generally speaking it has a close resemblance to the top section in the above drawing. I reamed out the hole to 5/8" (very poorly I would add) and used some 5/8 bronze bushings to take up the slack of the 1/2" tie rod

Then I made a wood prototype of the bottom section of the clamp - it doesn't have the styling of the casting but it works.

So I'm getting a block of steel to replicate the wood prototype. The question is how to join the two parts - more specifically how to prepare the joint lines. My initial thoughts were to mill the appropriate angle on the arm so that butts against the upper block and weld but is that a good joint for welding? Should I leave the angle alone and use the gap for welding? Should I leave a gap by milling a smaller angle? Lots of stuff I don't know about welding and joint preparation.

Thanks for your thoughts

Rick

Then I found this laying around the scrap pile

The arm is a bit long and the hole is oversized but generally speaking it has a close resemblance to the top section in the above drawing. I reamed out the hole to 5/8" (very poorly I would add) and used some 5/8 bronze bushings to take up the slack of the 1/2" tie rod

Then I made a wood prototype of the bottom section of the clamp - it doesn't have the styling of the casting but it works.

So I'm getting a block of steel to replicate the wood prototype. The question is how to join the two parts - more specifically how to prepare the joint lines. My initial thoughts were to mill the appropriate angle on the arm so that butts against the upper block and weld but is that a good joint for welding? Should I leave the angle alone and use the gap for welding? Should I leave a gap by milling a smaller angle? Lots of stuff I don't know about welding and joint preparation.

Thanks for your thoughts

Rick