- Joined

- Apr 5, 2016

- Messages

- 26

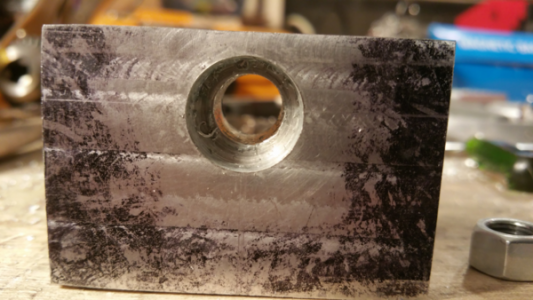

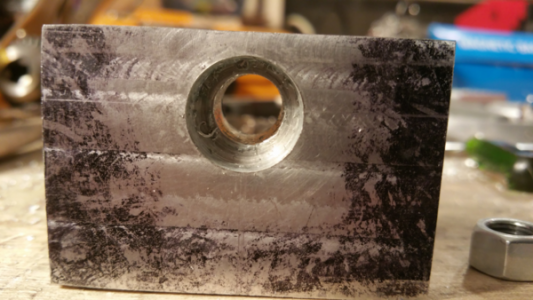

I did finally get my Bearing block milled, But it took me 4 tries...

So I did learn not to take off too much .20 to .30 each pass, but the one thing i had issues with even with the block I got to work was centered in the hole.

So enlighten me please on how to use this Boring Head...

My order now is of course drill the hole (15/32") then use boring head. I have to use a drill chuck for drilling the hole. Then I don't move the table and insert the boring head with the unit set to zero. I open up the boring head to just scrape the inside of the hole and then go from there. Problem is unit is not centered. I have had to adjust the table a slight bit to get it to cut center of the pilot hole. Then the issue comes in when I have to flip the block over and do side 2. Getting it centered is bear..

So what is the trick? Is this just crappy tool or am I doing something wrong?

So I did learn not to take off too much .20 to .30 each pass, but the one thing i had issues with even with the block I got to work was centered in the hole.

So enlighten me please on how to use this Boring Head...

My order now is of course drill the hole (15/32") then use boring head. I have to use a drill chuck for drilling the hole. Then I don't move the table and insert the boring head with the unit set to zero. I open up the boring head to just scrape the inside of the hole and then go from there. Problem is unit is not centered. I have had to adjust the table a slight bit to get it to cut center of the pilot hole. Then the issue comes in when I have to flip the block over and do side 2. Getting it centered is bear..

So what is the trick? Is this just crappy tool or am I doing something wrong?