- Joined

- Jan 2, 2011

- Messages

- 331

Did you get the rebuild book? It was very helpful to me when I set my spindle. You might look in my thread of my rebuild. I think I posted pics of the indicator set up. Remember it should turn freely by hand and should not get hot when running.

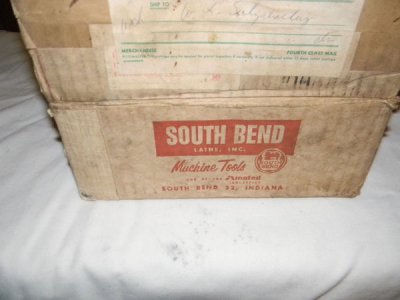

Got the missing bearing cap allen bolts from the hardware store today. Amazingly, other than the clutch knob screw, these were the only parts missing from the lathe when I bought it slightly disassembled, although I misplace the take up nut but was able to get one from the ebay seller who sold me the used bearings. I couldn't wait to snug everything down to see where I was at. Not surprising, an excessive amount of up and down play on both ends due to the new laminated shim set. Although it turned fairly easy, it felt a little grabby.. You would think with that much play, that wouldn't be the case, but then again, these are not the original bearings. Maybe they need to break in to the different spindle. I'm so tired from staying up , I abandoned it for the night and came back into the house. Sometime you need to walk away. I obviously need to check the play with a dial indicator and see how many layers I need to remove. Also I need to read up on the process. My South Bend CE3458 parts manual has a great section on spindle assembly and adjustment, with some nice drawn pictures. Greg, I plan on looking at your restore thread for some additional tips.