- Joined

- Nov 8, 2011

- Messages

- 1,678

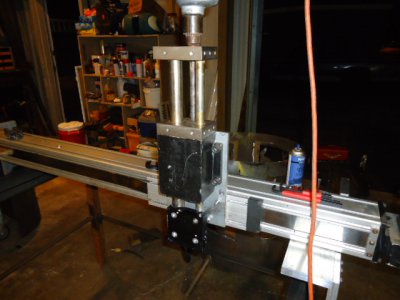

Got the gantry mounted and rolling smoothly, Only have one set of skates on each side & it is still very stable as far as rocking, it does have a bit of movement as far as one skate getting ahead of the other when pushing from one side but that is expected & will be eliminated when the second set of skates are mounted. Gotta order the skates when I get some cash.

Next item to work on is the drive mechanism to power the gantry down the X axis tracks. I need a piece of rod to make an axle to reach from one side to the other, make the mounts for the tensioned chain (stationary) that a sprocket will run on. Need to make a gear reduction system and get all that mounted along with the stepper motor.

The Y axis is all internal in the gantry so that makes things easier.

Next item to work on is the drive mechanism to power the gantry down the X axis tracks. I need a piece of rod to make an axle to reach from one side to the other, make the mounts for the tensioned chain (stationary) that a sprocket will run on. Need to make a gear reduction system and get all that mounted along with the stepper motor.

The Y axis is all internal in the gantry so that makes things easier.

:yikes:

:yikes: