- Joined

- Feb 14, 2020

- Messages

- 166

I think you are using the drum switch between the VFD and the motor, and that is a HUGE NEVER DO for a VFD. You always hard wire the VFD to the motor. Switching while running causes huge voltage spikes, these exceed the transistor break down voltage. I'm guessing you blew up your VFD. And it should have error'd out on this. You may have been doing this for a long time, but I'm believing this finally failed.

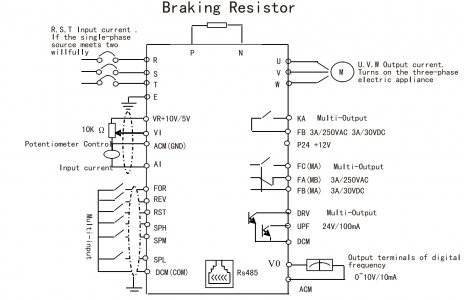

Gotcha, didn't know that. But it looks like the VFD survived that mistake as it just ran my 3-phase belt grinder motor without a hiccup. When I get this resolved, I'll eliminate that drum switch. I'm assuming there's some other type of switch that can be wired directly in to the VFD to switch directions and turn on/off? The VFD is mounted on the side of my machine and would be a ***** to turn it on and off in its current location.