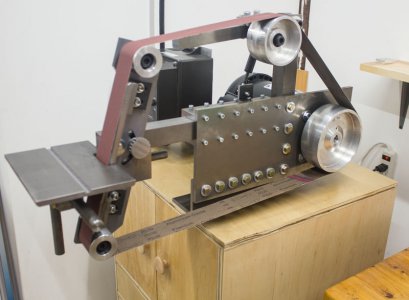

I took mikey's advice and built a 2X72 belt sander from scratch and quickly added the glass platen. See my journey

here.

As far as cost, the 3-phase, 2-HP motor and VFD cost well over $500 alone. I could have went with a cheaper VFD, but decided to get one with a safety rating. Mine passed the UL standards. Plus, this one requires no programming. You just set some jumpers for the settings. It's been working great so far. I'm sure I spent over $1000 on this, but it was fun and quite a learning experience and is better made than commercial ones at this price point.

I did buy the wheels off of a seller on eBay since I don't think I could have made them accurately on my mini-lathe.

Most of the plate stock is 3/8" (~9.5 mm) thick. I don't weld, so I made it to be bolted together. It's rock solid and is probably overbuilt.

I designed it in FreeCAD and this helped tremendously as it shows how parts fit together (or not!) and shows clearances, interactions, etc.

This grinder has become my workhorse and I'm not sure how I got along without it.