-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Belt or disc

- Thread starter ltlvt

- Start date

- Joined

- Jan 20, 2018

- Messages

- 5,637

I have a 6x48 with disc. I keep a 60 grit belt and 80 grit disc on it. The belt gets used 80+% of the time, for stock removal and squaring. I frequently use it instead of milling the ends of a part. The disc gets used for more delicate chamfering and finer work. The belt lasts longer and holds up better than the disc. I finally found reasonably priced zirconia (blue) belts and discs. HUGE improvement over HF AlOX.

- Joined

- Feb 9, 2017

- Messages

- 5,250

Had to look back through account and I bought the belts in 2017! And I’m still on the first belt and my first disk. They are Red Label zirconium. I think that’s a reflection of how little I use the belts. I bought just one disk pad from them to try out and it’s still usable. I think like the belts its 80grit. I kinda like them more a little worn as they really cut. It’s my first zirconium and they are really good compared to the old belts that came with the MultiTool.My disc is 12 " I too would be interested in what brand and where you get yours.

- Joined

- Feb 9, 2017

- Messages

- 5,250

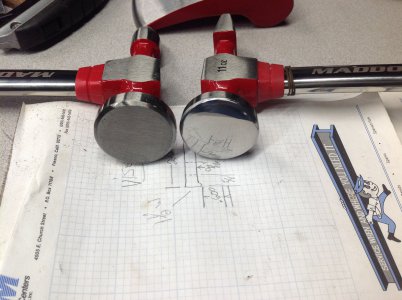

I only use my belt sander when I’m polishing. There is a great kit from MultiTool that has this selection of belts along with one that is some kind of weaved belt for polishing along with selection of rouge. Never done polishing before but it did a wonderful job on my sheetmetal hammers and my first anvil for my planishing hammer. Mirror finishes one both. One being my HF hammer. Talk about a diamond necklace on a pig! Also did a great job on my wheel and anvils on my English wheel.

Attachments

- Joined

- May 7, 2023

- Messages

- 1,372

This is the primary reason I sought out a 6x48 belt only machine.I have a 6x48 with disc. I keep a 60 grit belt and 80 grit disc on it. The belt gets used 80+% of the time, for stock removal and squaring. I frequently use it instead of milling the ends of a part. The disc gets used for more delicate chamfering and finer work. The belt lasts longer and holds up better than the disc. I finally found reasonably priced zirconia (blue) belts and discs. HUGE improvement over HF AlOX.

The disks were as you're constantly using the (Relatively) same spot and they also do not have as much surface area as a belt, which again makes them wear quicker.

We have a belt/disk machine at work and the disk table just turns into a catchall where things wind up getting worked over onto the disk at random. Its handy for the coolant pot though.

- Joined

- Jan 1, 2018

- Messages

- 1,160

My father brought home this Walker Turner from work in pretty bad shape. I spent half of summer taking it apart, cleaning it all up, straightening a few things and painting it. He helped me replace the bearings. It has a horizontal only platen for the belt sander. I find I use both the belt and the disc. I use the sander more for metal than wood but it sees a good amount of both.

The sander has held up quite well these past 42 years. The paint could use a little touch up and some day I should paint the start / stop control box like I have always meant to. This was the first of about a dozen machines I have bought for cheap, fixed up and put back into use since the refurb when I was about 14 yo. My father got this one for free. The maintenance department took it off the books to toss and my father was the plant manager so it went into the back of our Ford country Squire station wagon.

As far as having both a disc and belt sander, it is nice to have both but IMHO there is certainly no need to have both!

P.S. I have been using 4" x 52 1/2" belts from Red Label Abrasives. They stock the proper length for "this" machine so they cost about half of what having custom made belts cost else where.

I have had really good luck with Red Label Abrasives. Quality belts and discs at reasonable prices.

The sander has held up quite well these past 42 years. The paint could use a little touch up and some day I should paint the start / stop control box like I have always meant to. This was the first of about a dozen machines I have bought for cheap, fixed up and put back into use since the refurb when I was about 14 yo. My father got this one for free. The maintenance department took it off the books to toss and my father was the plant manager so it went into the back of our Ford country Squire station wagon.

As far as having both a disc and belt sander, it is nice to have both but IMHO there is certainly no need to have both!

P.S. I have been using 4" x 52 1/2" belts from Red Label Abrasives. They stock the proper length for "this" machine so they cost about half of what having custom made belts cost else where.

C-Bag do you remember what brand and grit you have been using ? The ones I’m using on my little disc / belt sander don’t last long at all

I have had really good luck with Red Label Abrasives. Quality belts and discs at reasonable prices.

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,250

My MultiTool is horizontal too. At first I thought it weird but for precision grinding the disk is perfect for me. The difference from the Walker Turner is it’s mounted to a grinder and the belt sticks straight out front with no table underneath. So I have access to the unsupported bottom of the belt. Perfect for polishing the hammers, English Wheel parts and the planisher anvil where you want curves. That’s wonderful you’ve been able to save those cool old machines.

I really really like my 300 mm disc sander.

But ..

It´s heavy, about 20 kg, from chester uk.

About 750W, real, iirc.

And really quiet.

And really really fast for quick polishing and cleaning up of edges, and medium sized workpieces.

And I use a specialist metal removal disc on it, from a uk supplier, blue belt, about 60 grit, afaik.

Seems to last a long time.

And makes great edges and chamfers in tool steel, a few seconds.

Upto about 150 mm workpieces.

And it was about 220£, maybe 6 years ago.

But ..

It´s heavy, about 20 kg, from chester uk.

About 750W, real, iirc.

And really quiet.

And really really fast for quick polishing and cleaning up of edges, and medium sized workpieces.

And I use a specialist metal removal disc on it, from a uk supplier, blue belt, about 60 grit, afaik.

Seems to last a long time.

And makes great edges and chamfers in tool steel, a few seconds.

Upto about 150 mm workpieces.

And it was about 220£, maybe 6 years ago.

- Joined

- Feb 9, 2017

- Messages

- 5,250

This is one of the many great things about working in my own shop. I don’t have meatheads wondering about leaving destroyed machines in their wake. I got schooled early on that you prematurely wear out grinder wheels, belts and disks just working one spot. So I’ve always been phobic about staying in one place and work the whole surface of whatever I’m grinding. Add to this these new zirconium belts and disks they just seem to last forever and cut fast.The disks were as you're constantly using the (Relatively) same spot and they also do not have as much surface area as a belt, which again makes them wear quicker.

This is why I’m a bit perplexed by the use of 2” wide belts. Yeah they are like 72” long but having only 2” wide to work would seem to wear the belt quicker. I do see the need for a narrow belt for getting into tight places and it would have been handy for a project I did recently where I was rounding off the ends of small links. I do have a small handheld HF 1” wide belt grinder that I can mount to a table to do these tiny intricate jobs.