-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Basic question

- Thread starter Meir

- Start date

- Joined

- Sep 10, 2013

- Messages

- 562

Google FireBall tools welding table. You can buy the 12x12 inch cast iron plates to build a welding/assembley table. I mean if you need that kind of table. It will be cheeper to buy them and build it with them. Cast iron is better with weld spater so you don’t have to grind on the table, which will keep it flat and level.

Just an idea.

CH

Just an idea.

CH

Think about the reach of your clamps. 2” spacing in a grid is awfully close. My F style clamps have a 4” reach so even 8” spacing would still allow clamping anywhere on table. 4 or 6” might be better for stability and keep from warping. Annular cutter might do better for you holes you won’t be cutting a full slug. Wouldn’t think you’d want a countersink or relief on holes. The clamp might not bind in hole and slip out.

- Joined

- Dec 2, 2012

- Messages

- 1,734

Why does your design require so many holes? Secondly, what material are these plates to be made of?

mark

I've got a grid of M12 threaded holes on my welding table that I made, very handy for bolting stuff down with.

Stu

Guys. you are awesome!

i did not expect so many replies.

i will try to answer some of your comments.

the top plates are 1/2" thick hot rolled steel. the multiple 5/8" holes are to allow me to create jigs using various tools.

this is not my design, but based on existing products.

this is just one example:

my design is a bit different, as im using materials i have in hand, but the concept is the same.

the standoff with the 3/8" holes, are welded to the frame, and allow adjustment of the plates to create an even level surface.

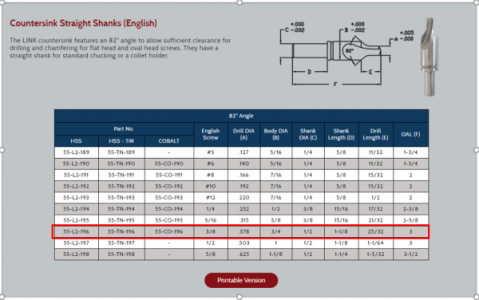

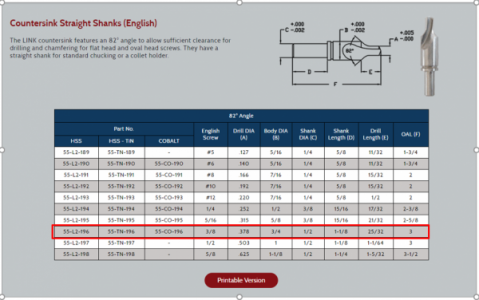

i got the standoffs from fireball tools, and jason was the one recommending the LINK 65-L2-292 drill bit.

i guess he assumed i have a mill.

this is the standoff. the lock nut enable the adjustment of the plate height.

the tool i need is LINK 55-L2-292. this is the only place i found it online.

www.dgisupply.com

price is great. the only problem they have a minimum of 10.

www.dgisupply.com

price is great. the only problem they have a minimum of 10.

the tapered one that i have, i got from MSC for $31 plus shipping, but they don't have the 55-L2-292 with the straight shank in the online catalog.

i went to the LINK website, and apparently they have a distributor 10 minutes away from me (im in FL, Fort Lauderdale area).

i will pay them a visit tomorrow.

i did not expect so many replies.

i will try to answer some of your comments.

the top plates are 1/2" thick hot rolled steel. the multiple 5/8" holes are to allow me to create jigs using various tools.

this is not my design, but based on existing products.

this is just one example:

my design is a bit different, as im using materials i have in hand, but the concept is the same.

the standoff with the 3/8" holes, are welded to the frame, and allow adjustment of the plates to create an even level surface.

i got the standoffs from fireball tools, and jason was the one recommending the LINK 65-L2-292 drill bit.

i guess he assumed i have a mill.

this is the standoff. the lock nut enable the adjustment of the plate height.

the tool i need is LINK 55-L2-292. this is the only place i found it online.

#10 HS Counter Drill D405 | DGI Supply

the tapered one that i have, i got from MSC for $31 plus shipping, but they don't have the 55-L2-292 with the straight shank in the online catalog.

i went to the LINK website, and apparently they have a distributor 10 minutes away from me (im in FL, Fort Lauderdale area).

i will pay them a visit tomorrow.

Thinking about using your taper shank bit in a chuck. It would be simple enough to grind the shank using a hex collet block to grind straight flats on the shank. Easy peasy and it would hold better in a chuck..............Bob

Thanks bob. but i have no machining equipment or skills. at the moment at least.

Think about the reach of your clamps. 2” spacing in a grid is awfully close. My F style clamps have a 4” reach so even 8” spacing would still allow clamping anywhere on table. 4 or 6” might be better for stability and keep from warping. Annular cutter might do better for you holes you won’t be cutting a full slug. Wouldn’t think you’d want a countersink or relief on holes. The clamp might not bind in hole and slip out.

the Holes in the attached drawing will be done using an 5/8" annular cutter. only the 3/8" holes for the standoffs, will have the countersink for the screw.

I’m sure you already thought of this option, but if you hadn’t I will suggest...fabrication businesses have laser cutting available that can get you what you want quickly. I have a good friend who owns a large shop where they can cut up to 2” on their laser cutter.....even those holes you want put in, just an option as that is a lot of holes to drill by hand.

that was my first thought. i got quoted $750 for the 4 plates (sound reasonable price now

), but i figure i can use that money to buy tools i can keep (yes. another tool junkie here).

), but i figure i can use that money to buy tools i can keep (yes. another tool junkie here).- Joined

- Dec 21, 2018

- Messages

- 48

The reason its tapered is because its 'indexable' I have several smaller ones like that that fit into the end of a shank. The shanks are very long, so that way when you wreck a center drill you don't have to buy an expensive extended drill, you just buy the cheaper insert and you've got a brand new center drill. it may be worth while to look into getting the shank, its probably cheaper than a new center drill with a straight body, and you can just cut it down and use it in the drill chuck.

The reason its tapered is because its 'indexable' I have several smaller ones like that that fit into the end of a shank. The shanks are very long, so that way when you wreck a center drill you don't have to buy an expensive extended drill, you just buy the cheaper insert and you've got a brand new center drill. it may be worth while to look into getting the shank, its probably cheaper than a new center drill with a straight body, and you can just cut it down and use it in the drill chuck.

can you be kind and direct me to one that can fit my application?

thanks in advance.