-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad motor or spindle bearing going bad?

- Thread starter Brento

- Start date

Stupid question but if i need to add a shim for the headstock do i cut the shim to the shape of the other shims or do i just make a little rectangular piece to fit in. I am ordering some shimstock tonight. Tmr i will put the spindle in and check what i have and if i need any shimstock. I have the felt soaking tonight.

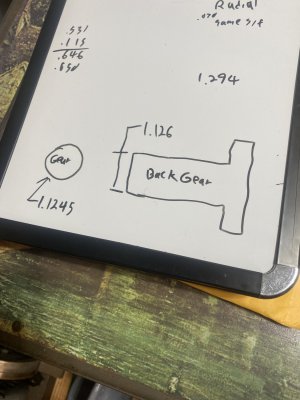

Ive got everything back together minus the back gear. No overheating so that is fixed. I notice i have a little hard spot when i free hand the spindle. Always at the same spot. If i disengage the bull gear and move the spindle cone pulley it is free so it is on the right side. I did the bearing test and the bull gear side was at the .002 mark.

Found the culprit. I added needle bearings to the back of the take up collar instead of the fiber washer. Some have said it helps with the radial movement. Well that collar now sticks out a touch farther then normal and engages with the reverse gear casting. I took that off and filed some material off and it is good to go. Now to set up my 4 Jaw and cut my back gear off for the ebay replacement. I think im gonna go with freezing the back gear assembly and heating up the gear and place it on. I was thinking a .0015 or so should be enough for that fit?

- Joined

- Sep 24, 2020

- Messages

- 1,917

Let me know what you think of the Kit, I am considering it.Found the culprit. I added needle bearings to the back of the take up collar instead of the fiber washer. Some have said it helps with the radial movement. Well that collar now sticks out a touch farther then normal and engages with the reverse gear casting. I took that off and filed some material off and it is good to go. Now to set up my 4 Jaw and cut my back gear off for the ebay replacement. I think im gonna go with freezing the back gear assembly and heating up the gear and place it on. I was thinking a .0015 or so should be enough for that fit?

Well it has been a little while to get back to finish the lathe. Been a little crazy here. I froze the back gear assembly for a week by the time i got to it (woops). I set it up in the press and i heated up the gear and it slipped on most of the way leaving maybe 50 thou to push on. All in all i like the back gear fix. I decided the light press fit was the way to go but if it fails i can go back and do the loctite if need be. At this point my headstock has been fully redone and ready to make some chips. Now to do damage control in my shop since i left the garage door open for 30 minutes and everything sweat like crazy.

Attachments

-

83038B97-8F6E-4294-8780-7DF2B3D4306B.jpeg274.9 KB · Views: 6

83038B97-8F6E-4294-8780-7DF2B3D4306B.jpeg274.9 KB · Views: 6 -

383BC011-8E6D-46D9-9202-09415B88A83E.jpeg275.7 KB · Views: 6

383BC011-8E6D-46D9-9202-09415B88A83E.jpeg275.7 KB · Views: 6 -

A284C06F-4104-45E3-AF89-61BD8AB19E46.jpeg175.1 KB · Views: 5

A284C06F-4104-45E3-AF89-61BD8AB19E46.jpeg175.1 KB · Views: 5 -

AFEBA367-B042-4A66-ABBF-65354EE6AFB3.jpeg215.8 KB · Views: 5

AFEBA367-B042-4A66-ABBF-65354EE6AFB3.jpeg215.8 KB · Views: 5 -

9B3EEEB9-E728-4525-A2E9-27E83AA292E9.jpeg199.6 KB · Views: 5

9B3EEEB9-E728-4525-A2E9-27E83AA292E9.jpeg199.6 KB · Views: 5 -

17E1978F-2121-4021-A737-6C09A7DA0CB8.jpeg196.1 KB · Views: 5

17E1978F-2121-4021-A737-6C09A7DA0CB8.jpeg196.1 KB · Views: 5 -

EEA1E09F-0A96-4114-ADD9-523D37B23ABD.jpeg399 KB · Views: 5

EEA1E09F-0A96-4114-ADD9-523D37B23ABD.jpeg399 KB · Views: 5 -

2CA1B640-DB54-4D17-AC73-B26093E028C2.jpeg304.4 KB · Views: 5

2CA1B640-DB54-4D17-AC73-B26093E028C2.jpeg304.4 KB · Views: 5 -

A59D8521-C192-424C-851C-6C310878688A.jpeg297.8 KB · Views: 6

A59D8521-C192-424C-851C-6C310878688A.jpeg297.8 KB · Views: 6