- Joined

- Aug 5, 2015

- Messages

- 94

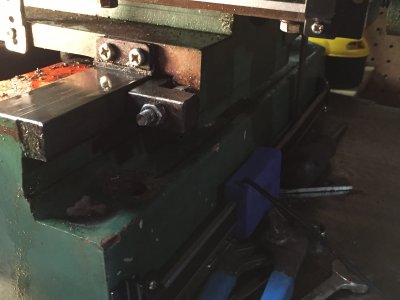

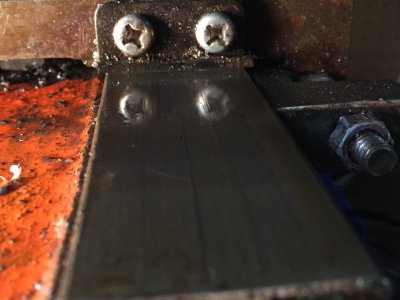

I am finally getting around to tuning up the jet -15 mill drill. I have yet another problem that I could you your wealth of knowledge with. The Y axis portion of the table lies flat against the ways as it travels towards me but as I switch direction the top section lifts away from the ways and jumps if you will. It remains to keep the 1/32" gap above the ways the entire way towards the column. I am unsure what to adjust in order to correct this issues. I do not have the manual for my machine. I have a pdf of a much newer similar model but the table assembly is different. This machine is pretty old maybe 79 or so. Made in Taiwan. Any insight to this issue would be very helpful.

Thanks

Dylan

Thanks

Dylan