- Joined

- Apr 28, 2014

- Messages

- 3,590

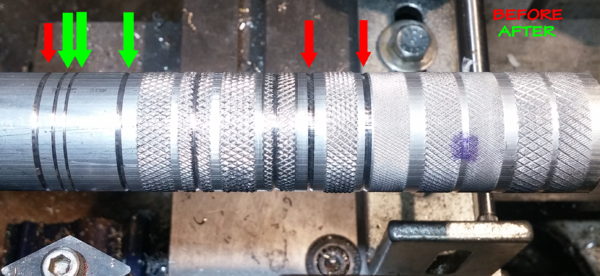

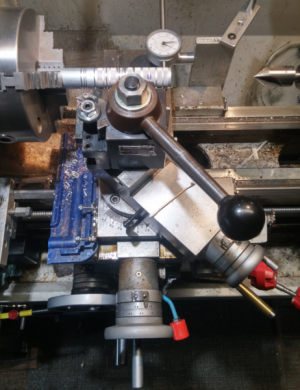

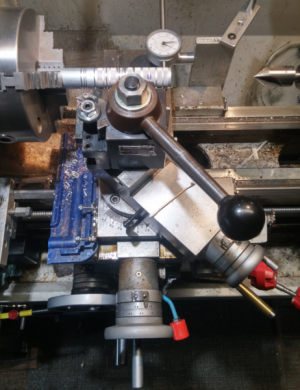

Quick run - no chatter! Compound is still at 45°. I didn't change the angle because the one hold-down nut is still a concern.

I may attempt to rework that tonight. May not succeed but it's good to have hope. - hehe

Tried it on a piece of 1" DIA. round and a hunk of 1" DIA. Tube.

Attached picture is of the solid round.

The grooves marked in red were the cuts I made a couple of days ago.

And I'm feeling that if I get it rotated to 30° it's be even better.

I may attempt to rework that tonight. May not succeed but it's good to have hope. - hehe

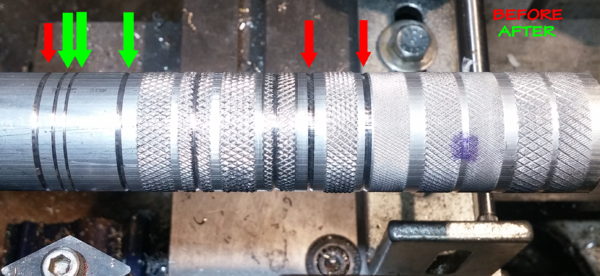

Tried it on a piece of 1" DIA. round and a hunk of 1" DIA. Tube.

Attached picture is of the solid round.

The grooves marked in red were the cuts I made a couple of days ago.

And I'm feeling that if I get it rotated to 30° it's be even better.