- Joined

- Jun 11, 2013

- Messages

- 731

So now you need to flip the back plate around on the spindle and indicate it up true. You may need to turn a off a bit of the threads to have it mate up to the register. Mate it up then indicate it to whatever part is registering the backplate to the chuck. (hope you understand) your actually going to be indicating the face that is facing the spindle. You might need shims to get it tight and indicated to 0, then face off the back side of the backplate that registers to the spindle and you should now have a perfect mating.

Hope I explained that right.

- - - Updated - - -

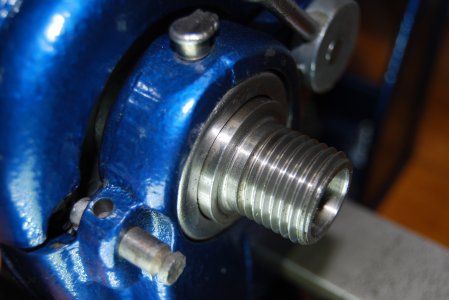

One other thing, can you take a picture of your spindle and a picture of the backplate end that normally goes onto the spindle? Perhaps your spindle is threaded up to the register and you just need to take a bit of thread off the backplate to have it mate up. Then we can check the runout.

Hope I explained that right.

- - - Updated - - -

One other thing, can you take a picture of your spindle and a picture of the backplate end that normally goes onto the spindle? Perhaps your spindle is threaded up to the register and you just need to take a bit of thread off the backplate to have it mate up. Then we can check the runout.