- Joined

- Sep 4, 2013

- Messages

- 494

Need I apologise If I bought it just because it'cute?..........BLJHB

Use of the steel rule works in any situation. Just visually make sure the steel rule is vertical to the bed of the lathe.Why spend money when you don't need to?

The lathe does not need to be level for this tool to work. It does not need it. The vial level is only to let you know when you have hit dead center between the cutter and the work piece. It is not used as a level per-say. It just lets you know when you are straight.

"Billy G"

. In post #14, I saidThere is no reason it shouldn't work. ..... This of course assumes a level lathe. You would best adjust the height by another method and use that setting to "calibrate" your height adjustment tool.

...... If you have leveled your lathe then fine, if not, I would calibrate the tool by checking a known good setup. (Actually, I would check it against a known good setup anyway because there is no guarantee that the tool is accurate out of the box)

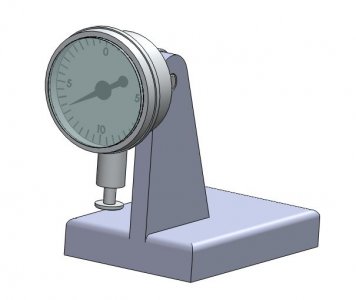

Tom Lipton from OxTool uses something similar. A further improvement would be to replace the upper cylinder with a dial indicator to read the offset amount. Even easier on the eyes. I have an old Ames dial indicator earmarked for that purpose.Here's a centering tool someone on the forum invented and I copied their idea. This has worked out awesome. I calculated the center height for my lathe then turned this simple tool, easy to see even for my old worn out eyes. I set all my tool heights with this and they have been spot on ever since.

Bob, level your lathe standing in as your conscience,..BLJHBIf you read, what I had posted, I said in post #2

. In post #14, I said

.

While I was not able to find the operating instructions for this product, I did find an operating manual for a product using the same principle from www.edgetechnologyproducts.com (http://store-1wa94vq6.mybigcommerce...ual/pro_lathe_gage/pro_lathe_gage_manual.html)

"Level Calibration

• For optimum results this unit should be calibrated to compensate for machines that have not been accurately leveled.

• Position the base of the gage on a flat surface of the lathe such as the compound or cross slide. The unit should be perpendicular to the axis of spindle rotation as shown.

• After loosening the adjustment screw the level housing can be rotated until the bubble is centered in the vial."

An uncalibrated tool will give you consistent tool height settings for your lathe and, depending on how close to level it is , they may very well be within the range of uncertainties. All I said, was to verify it against a known good setup.

The vertical steel rule method used by many will shift the tool height up or down by .01" on a half inch diameter workpiece with an error in estimating the angle of a little over 2 deg. Visually sighting against a center can present errors of .01" without too much effort. Turning to a zero diameter tit on the face of a piece of work is probably the most accurate but again, I am not sure you can do much better than .01".

I have used all three of those methods for many years and in reality, setting a tool height to better than .01" is probably not at all necessary. So yes, the tool will work and I would use it myself. But, for my own piece of mind, I would verify the calibration.

Bob