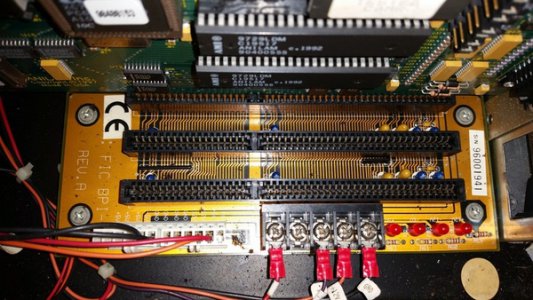

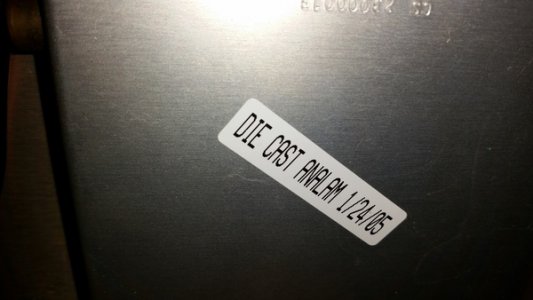

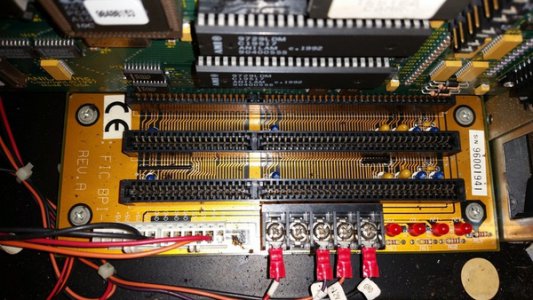

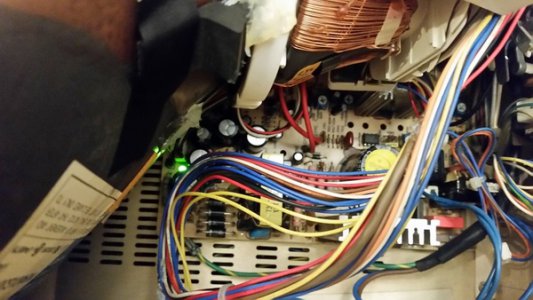

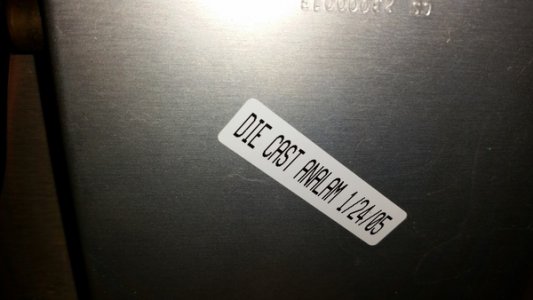

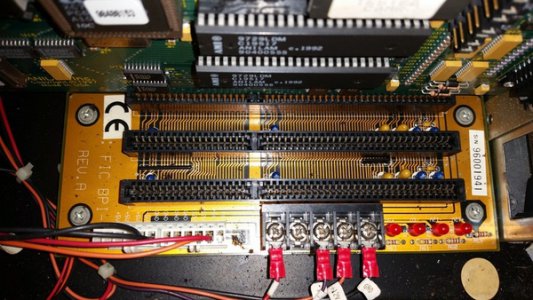

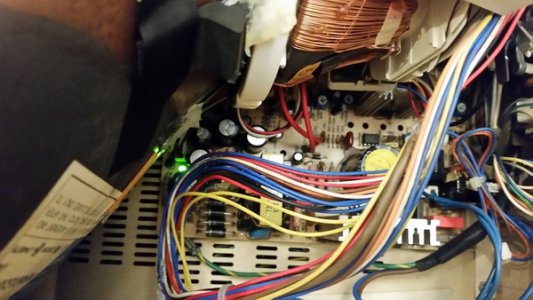

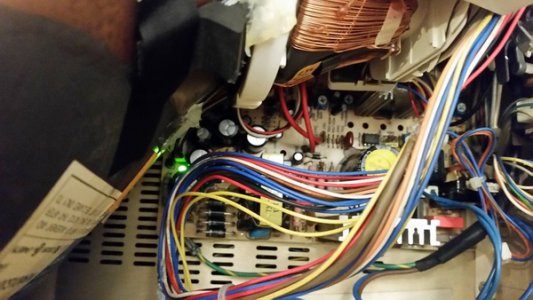

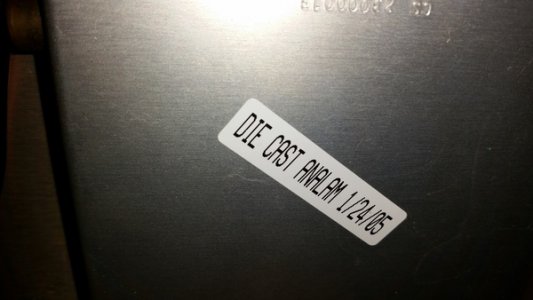

Ok fellas, I got the mill home and as expected the Anilam 3200MK doesn't "power up".

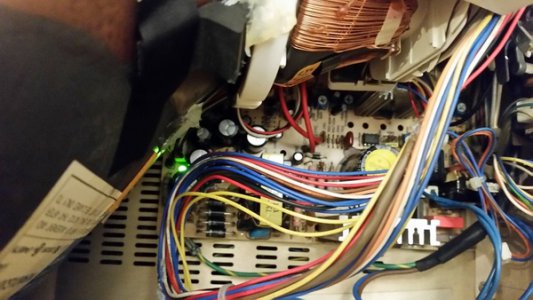

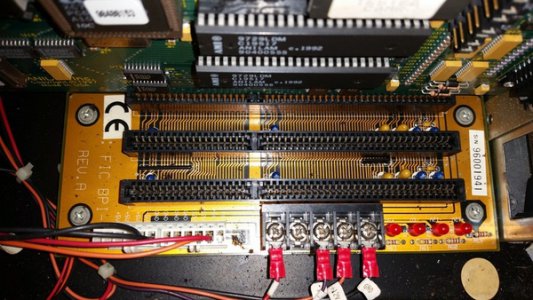

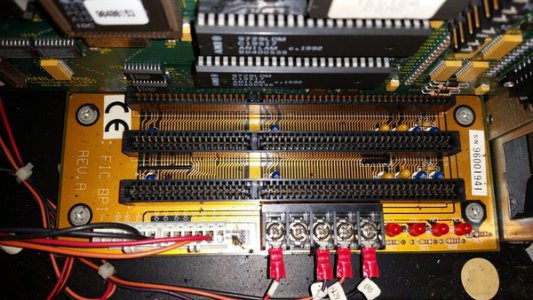

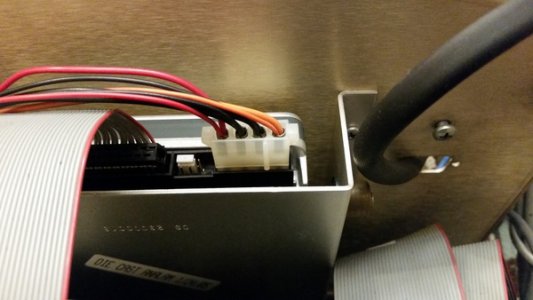

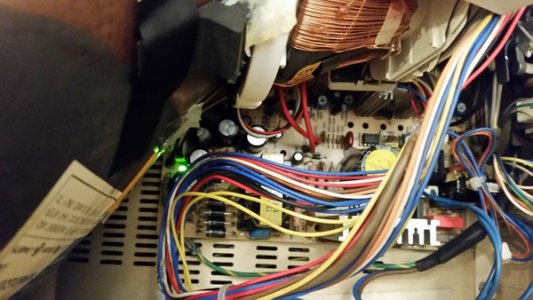

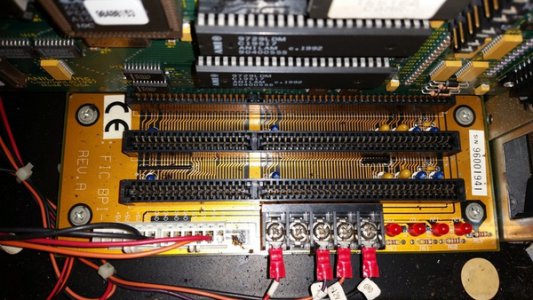

I have it on the bench now and trying to trouble shoot it. The guy I got it from said it had issues with the power supply. I have it plugged into the wall, you can hear the CRT sizzle and crackle to life, but no activity from the hard drive. I did probe the wires at the hard drive and couldn't find any voltage. I did play with the emergency shutoff, but no change.

I know there is a switch on the mill to turn the CNC controller on, but does this send a signal into the controller, or simply send power to the 110v power cable?

Does anyone have any manuals explaining the operation, or wiring diagrams? I have all the student manuals, and other operation type manuals. But nothing that would be useful in trouble shooting.

Thanks

Troy

I have it on the bench now and trying to trouble shoot it. The guy I got it from said it had issues with the power supply. I have it plugged into the wall, you can hear the CRT sizzle and crackle to life, but no activity from the hard drive. I did probe the wires at the hard drive and couldn't find any voltage. I did play with the emergency shutoff, but no change.

I know there is a switch on the mill to turn the CNC controller on, but does this send a signal into the controller, or simply send power to the 110v power cable?

Does anyone have any manuals explaining the operation, or wiring diagrams? I have all the student manuals, and other operation type manuals. But nothing that would be useful in trouble shooting.

Thanks

Troy

Last edited: