-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And so it begins, new PM-30MV...

- Thread starter sdavilla

- Start date

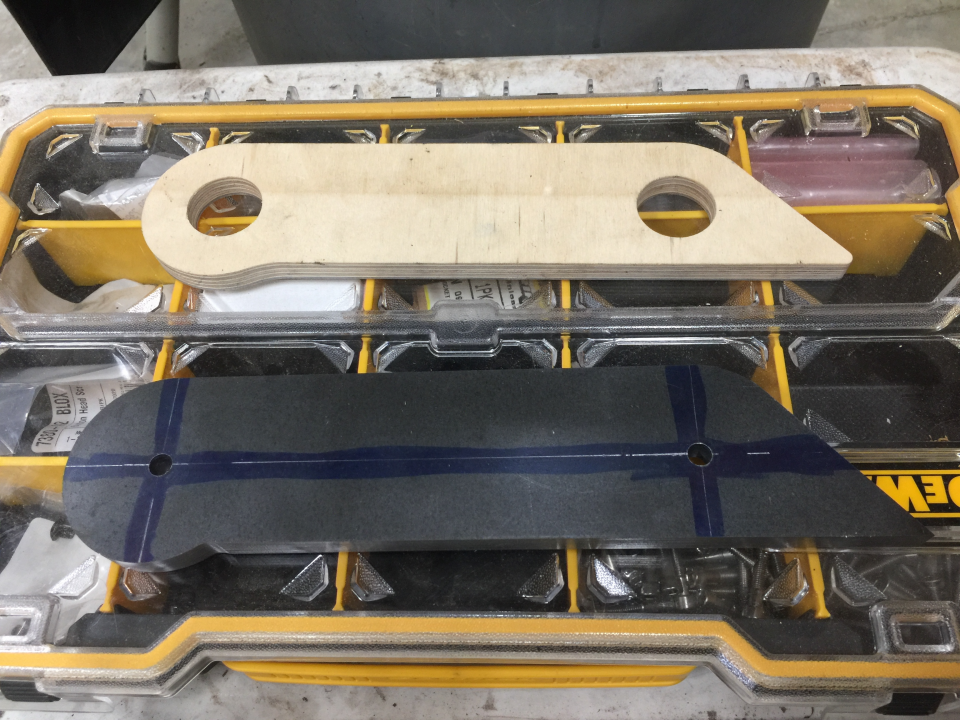

One piece almost done, needs a 1" plus a little hole for the bucket pins.

Little "opps" on rounded end. Looks worse that is from this angle. Serves me right for not laying out the entire outline. Next time, for sure.

My shop teacher would give me a B-, maybe higher if I showed that I learned my lesson on the other pieces... LOL. He's also say, "you know, davilla. You could have already cut that out with the torch and be done. But noooo, you have to have perfect edges." I'd just smile.

One thing for sure, DRO all the way for me. Amazing how much machining has advanced from the late 70's.

Little "opps" on rounded end. Looks worse that is from this angle. Serves me right for not laying out the entire outline. Next time, for sure.

My shop teacher would give me a B-, maybe higher if I showed that I learned my lesson on the other pieces... LOL. He's also say, "you know, davilla. You could have already cut that out with the torch and be done. But noooo, you have to have perfect edges." I'd just smile.

One thing for sure, DRO all the way for me. Amazing how much machining has advanced from the late 70's.