- Joined

- Aug 13, 2020

- Messages

- 1,342

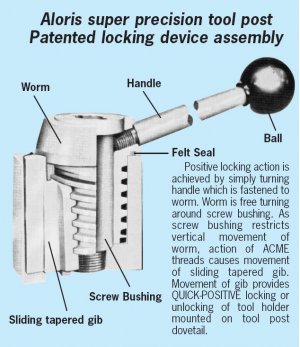

This is my question. We're talking machine tools, not jewelry. Do we really care if the bottom of the tool has a rough finish? I wouldn't care if any surface had a mill finish as long as there were no burrs and the tool position was dead-on repeatable.It’s been said by so many members in so many ways that the import holders are fine, functionally no better or worse than Aloris. In fact, the CXA holders I got recently through Allindustrial were superior in surface grinding than Aloris and were a bit longer, providing more holding leverage for the tool.

Please, if you think Aloris is “higher quality”, tell why you think that? Form, fit, function? I have not seen any issues.

I upgraded my homemade Norton style post, which was an upgrade to the lantern post, to a Chinesium knock-off of the Phase-II, and had enough money to get a holder for every tool I have. I went from 1/4" to 3/8" tooling at the same time, and that made the most drastic change in the quality of the cuts.

I was going to build my own, but it was cheaper to get the Chinesium toolpost than the steel and tooling to make my own, and I have other projects I wanted to get to.