O

ome

Forum Guest

Register Today

Hi guys ,

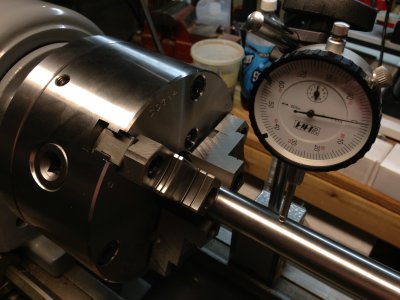

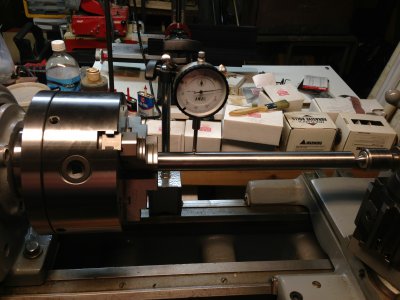

spent a fewe good hours and still makes that jump on the indicator all of a sudde

any ideas would be very helpful

thanks,

Jon

spent a fewe good hours and still makes that jump on the indicator all of a sudde

any ideas would be very helpful

thanks,

Jon