- Joined

- Aug 7, 2013

- Messages

- 655

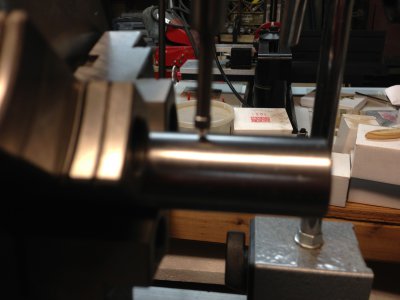

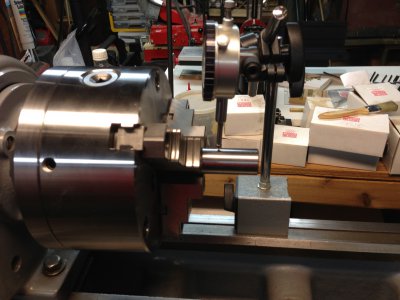

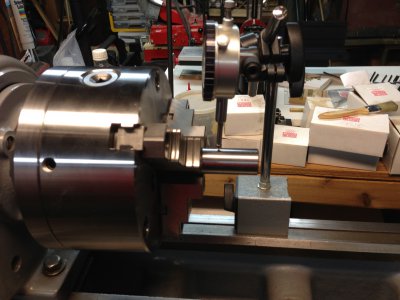

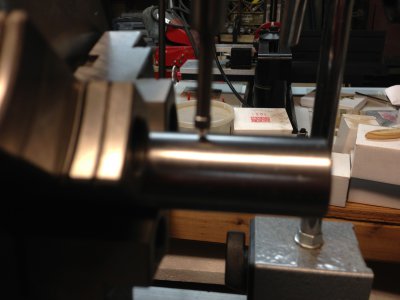

View attachment 62103View attachment 62102

I had my machinist friend make me up1" diameter test bar with a good center drilled at each end

i indicated off the test bar about 1.5" away from the jaws.

Thanks.

Jon

Depending on what you're machining, you're probably close enough.

Do you know how close the centers drills of the shaft are to the OD of the shaft?

If your headstock spindle will take the 1 inch shaft, chuck the shaft up short and measure the runout of the OD and center hole. Try the shaft a couple of different places in the chuck too. (loosen the chuck, rotate the shaft, tighten, check runout.)