-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few questions about my new to me South Bend 13"

- Thread starter OldBlue56

- Start date

- Joined

- Mar 21, 2018

- Messages

- 1,597

Agree with just using it. Keep an eye out for a SB 13" tailstock if you're a purist, but if it is aligned with your HS, it probably will outlast you. Broach in a slot for the hand wheel pinion shaft so that it can get the oil it needs - not that hard to do. You can also put a GITS oiler on top of the shaft boss on the apron casting (with a hole leading down to the wick), which a lot of SB owners have done.

- Joined

- Sep 28, 2013

- Messages

- 4,309

Looks like a great lathe to me! I think that tail stock may be a South bend, just not the one that would have shipped with that year. It looks allot like the one on my 1929 sb9, only difference being the split clamp on this one versus the 1/2 moon clamp on mine. The upper casting looks very similar as does the handwheel and nut.

I only have a passing knowledge of all the different variations, but at the end of the day all that matters is that it lines up with the spindle and it works.

I only have a passing knowledge of all the different variations, but at the end of the day all that matters is that it lines up with the spindle and it works.

Sounds good! That's what I figured as well, but didn't want to be wasting my time on a lost cause.

I'll probably just use the tailstock I have. Maybe make a longer handle so it's easier to lock the quill. I'll look into broaching a slot for the hand wheel shaft, may as well do it right if I have it apart. From my preliminary research doesn't seem like it would be too difficult just need to get the appropriate tools. I love any reason to justify buying more tools!

I'll probably just use the tailstock I have. Maybe make a longer handle so it's easier to lock the quill. I'll look into broaching a slot for the hand wheel shaft, may as well do it right if I have it apart. From my preliminary research doesn't seem like it would be too difficult just need to get the appropriate tools. I love any reason to justify buying more tools!

- Joined

- Apr 30, 2015

- Messages

- 11,329

Good article about old, worn lathes:

I did actually see that article and am going with that line of thinking on this one as well.Good article about old, worn lathes:

Adventures With Klunkers

Well this thing has definitely been messed with. I finally got the apron cleaned, upgraded and back together, but it certainly wasn't straight forwards...haha.

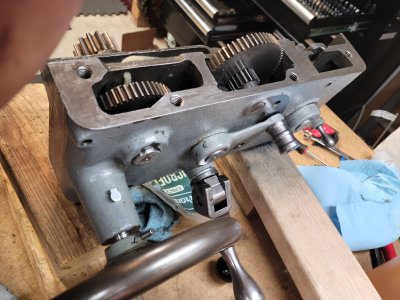

I broached a keyway and installed an oiler into the housing for the handwheel shaft so it can get some lubrication now. Had to make a bushing for the broach using my small grizzly lathe and PM-25MV mill, that was actually fun though. I figured at this point good to go, just through it all back together and move on.

That was not the case though. I eventually figured out that the previous owner must have tried to covert the clutch over to the lever operated version from the star knob and skipped a bunch of steps. It was missing a complete thrust washer and the set screw had not been drilled and installed in the housing to keep the handle from rotating. So I had to source a thrust washer based on measurement requirements I could make out then drill and tap the bottom of the clutch shaft housing for the set screw.

Now we are ready to just toss together and move on, but of course I managed to destroy one of the felt wicks. So now I suppose I will be down a wick later on in the project. Anyway got it all back together and everything appears to be operating correctly. The only thing unusual is the handwheel shaft appears to be quite a bit longer than necessary as you can see in the last picture. Also the hole for the taper pin is drilled off center in the shaft so only one hole in the hand wheel will line up and the taper pin will only go through the one side of the wheel and then the shaft but can't go all the way through due to the holes on the oppose side not lining up. I am wondering if the handwheel or the shaft is from a different sized lathe perhaps. I believe the wheel should mount further onto the shaft. Whatever though it will work just annoying to know it's there.

I am happy and relieved I got it all back together and seems to function correctly. Now onto the rest.

Cheers,

Brent

Attachments

- Joined

- Sep 28, 2013

- Messages

- 4,309

looks like you're doing good work! My guess would be that the carriage handwheel is a replacement. The taper pin holes are drilled and reamed for each shaft and handwheel, so a replacement wouldn't have the hole in the right place. You have a couple of options if you want to fix it and I would, as you may end up with too much side to side movement in the gear (I can't remember what's on the other side of that shaft). First is to redrill and ream for a taper pin further round the boss of the handwheel. Second is to tap that hole for whatever size set screw that would fit and file a flat on the shaft. Either would work just fine, they only differ in the tools needed.