Hello, I recently acquired a South Bend 13 and have been working on basically refurbishing it. This is not a full restore by any means I would just like to get it up and running. This was given to me by a family member who's father had passed away and they just wanted it out of their shop. I of course gladly loaded it up and took it home. So I don't really have any knowledge of previous use/care or anything other than she told me he was a gunsmith and used it for that. Unfortunately after I got it home and started actually inspecting it I found the bed ways are what I would consider pretty severely worn, so it won't be the most accurate piece of machinery every. However it might still be good enough for me to learn on and make some non-critical parts.

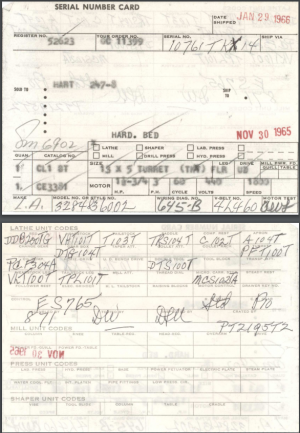

What I do know is the number on the bed is 10761TKX14, so it is a 13", with quick change gear, friction feed apron, underneath motor drive and special spindle. The cross feed was completely locked up and the longitudinal feed was very sticky, so I decided I better just tear the thing down clean and fix up whatever needs to be done. For this task I purchased the ILION rebuild kit and manual.

I have come across some inconsistencies and questions I just can't seem to find a good answer for and am hoping maybe someone on here might have some insight.

Cheers,

Brent

What I do know is the number on the bed is 10761TKX14, so it is a 13", with quick change gear, friction feed apron, underneath motor drive and special spindle. The cross feed was completely locked up and the longitudinal feed was very sticky, so I decided I better just tear the thing down clean and fix up whatever needs to be done. For this task I purchased the ILION rebuild kit and manual.

I have come across some inconsistencies and questions I just can't seem to find a good answer for and am hoping maybe someone on here might have some insight.

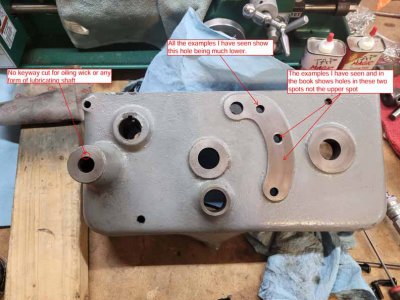

- The manual I have and every example I have found on the internet shows a keyway for an oil wick in the housing for the hand wheel shaft. My apron has no keyway or any way of providing lubrication for that shaft. Is this common and nothing to worry about or what do I need to do to get lubrication to that shaft?

- The layout of the holes for the feed change lever appears to be different from all the examples I have come across (see notated picture). Not sure this makes any difference in anything just something I noticed.

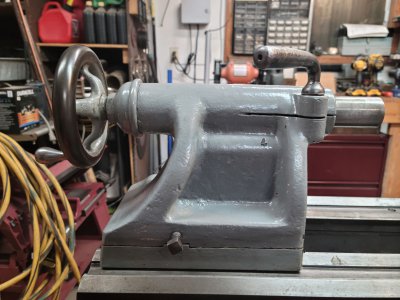

- The tail Stock has me somewhat baffled. As you can see from the picture it has no oilers of any kind on it where it should have one near the wheel and one on top for the quill (I think). It also does not have a cam lock design to lock the quill. On this one the handle is crewed down until the housing basically smashes the quill. Which on this is almost impossible to do by hand you would need a wrench or hammer to get this thing to lock, also probably the reason for all the what appears to be impact marks on the handle. This doesn't seem to be consistent with all the 13's I've seen. It does however measure correctly from the bed ways to the center of the quill. Any thoughts on this is this not that unusual or is this perhaps not the correct tail stock for the machine?

Cheers,

Brent