- Joined

- Sep 24, 2010

- Messages

- 3,096

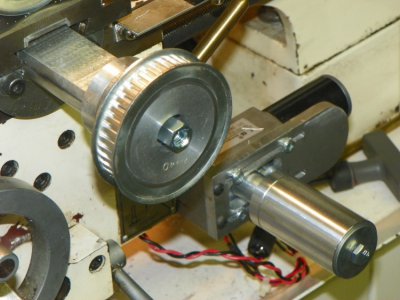

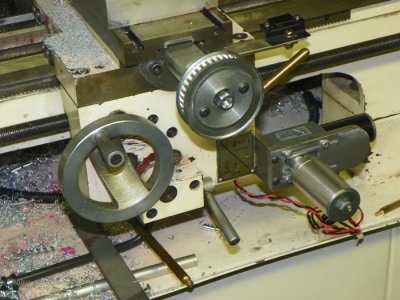

What kind of Pulleys are you waiting for Bill? Unique to the 9X or a McMaster or other vendor available part? Believe it or not if it is a factory only kind of part you might call HF technical and they have a supply of parts that is sometimes very esoteric but might contain what you need. I know for a fact they stock back plates for using dogs so you never know about them till you try.I'm dead in the water till the pulleys arrive. I've gone as far as I can go. Bummer.

"Billy G"

Bob