- Joined

- Feb 2, 2014

- Messages

- 1,068

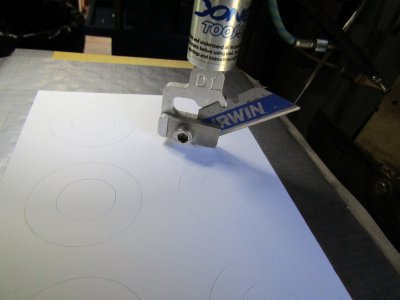

Making valves today.

You can't do a production run on the valves as the stem and seat must be made at the same time without removing the stock from the collet. They must be concentric and that takes a lot of fiddling around with the cross slide and angles.

Here are a couple of shots showing the setup.

Making the stem.

Making the seat.

The finished product.

Family shot.

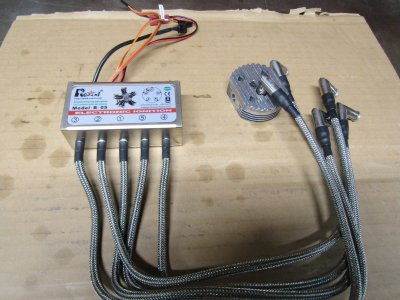

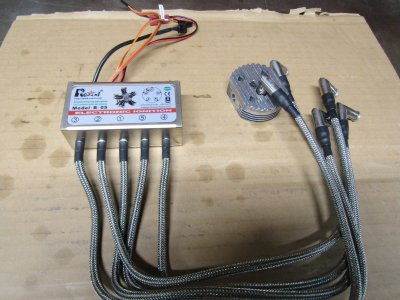

The valves still need to be lapped and checked for sealing before the heads are installed but my ignition module came in today.

They fit the spark plugs perfectly and the 90 degree end will make for a nice compact installation.

I will have to stop with the valves for now and mill a place in the nose housing for the hall sensor to mount in. I want to have that done before I install any of the heads.

Thanks for looking

Ray

You can't do a production run on the valves as the stem and seat must be made at the same time without removing the stock from the collet. They must be concentric and that takes a lot of fiddling around with the cross slide and angles.

Here are a couple of shots showing the setup.

Making the stem.

Making the seat.

The finished product.

Family shot.

The valves still need to be lapped and checked for sealing before the heads are installed but my ignition module came in today.

They fit the spark plugs perfectly and the 90 degree end will make for a nice compact installation.

I will have to stop with the valves for now and mill a place in the nose housing for the hall sensor to mount in. I want to have that done before I install any of the heads.

Thanks for looking

Ray