- Joined

- Jan 22, 2012

- Messages

- 655

Gunrunner you need to order a set of these for the Z axis hand crank. Bill did you just spit coffee on your monitor? :rofl:

View attachment 253356

View attachment 253356

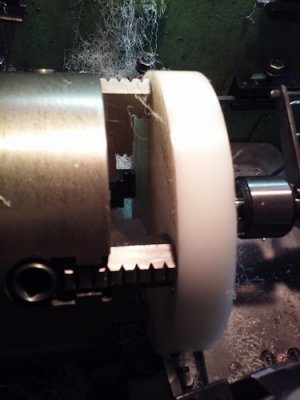

If you look at the build thread you will see more detail. You use the 4 cap screws on the top kind of like a 4 jaw chuck. Once it centered you lock down 3 holding screws and it is pretty robust in maintaining center.Robert

'Tis beautiful to behold, well done! What method did you use to center the vertical optical axis to the rotational axis of the mill?

it's because america has lost it's mind . A kid cant be a kid today . They say or do one stupid thing and they will get tar and feathered for life , law suits ....when I was in school, a teacher would give you a good "whack" or bounce you off a wall . Result was you never did it again. You behaved and grew up a decent and productive citizen . Now they just put a lawsuit on the kid and or parent , tarnish them for life .Could you imagine the trouble we would be in today if we tried half the stuff we did as kids. Not to mention the trouble our parents would be in as well. Like my 3 year old grand son did last night, he took a little tow motorcycle the fit in his hand perfectly, then attached a piece of split plastic pipe to it, and was walking around going bang bang. Could you imagine if he did that at school.

Depends, do you need to be able to undo the screw? If not put a dab of weld on the end. Also how much work is the pully going to do and how fast will it run? If you expect it to do a lot of work and at high speed I'd be inclined to make a sleeve to fit over the screw and be a tight fit between the sides of the shackle, then open up the bore of the wheel and put a small ballrace or two, or a bronze bush, in it like out of a skateboard they are very cheap and usually quite good.

Did you add sticky tape to the chuck side?

Rather than perching the disk on the ends of the jaws, try removing the jaws and pushing the disk against the face of the chuck body. As someone else mentioned, some double faced tape on the faying surfaces is another good idea.