So, indicating the back plate found a couple thous of run-out on the face, probably caused by not being super-careful the first time I mounted it. The circumference of the register was pretty much perfect. Refacing it got me to within one thou of run-out on the chuck's taper.

I did notice that the variation moved around a bit as I torqued the bolts. I'm going to get out the tenths indicator and a torque wrench to see if I can get in a bit closer.

Sent from my Pixel XL using Tapatalk

I did notice that the variation moved around a bit as I torqued the bolts. I'm going to get out the tenths indicator and a torque wrench to see if I can get in a bit closer.

Sent from my Pixel XL using Tapatalk

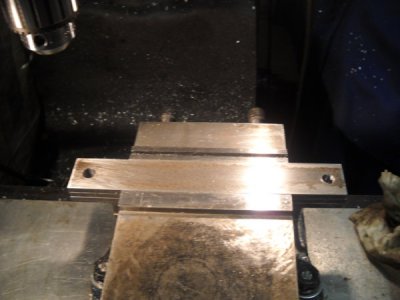

![20170619_172130[1].jpg 20170619_172130[1].jpg](https://www.hobby-machinist.com/data/attachments/193/193221-c8f74406bece54c98d913f78cc175c0a.jpg)