- Joined

- Apr 21, 2015

- Messages

- 894

Yep.

Sent from my SPH-L300 using Tapatalk

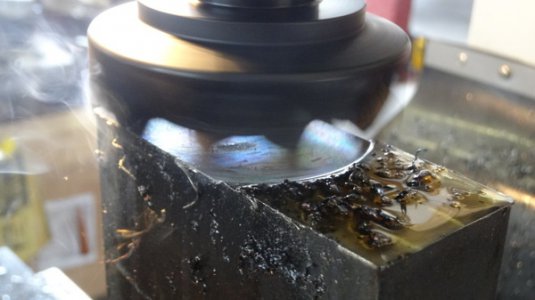

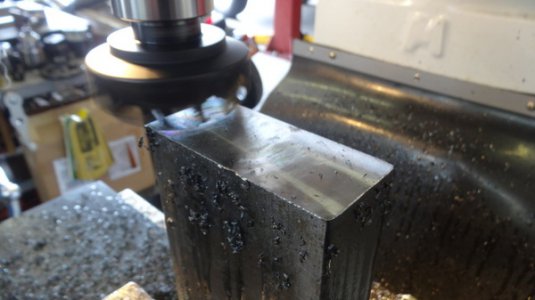

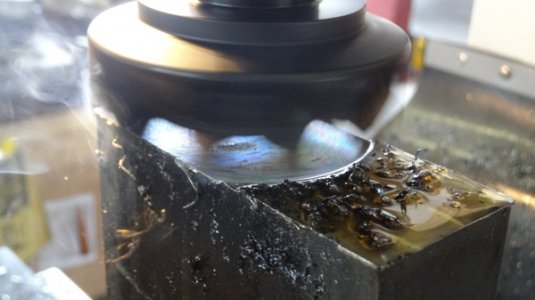

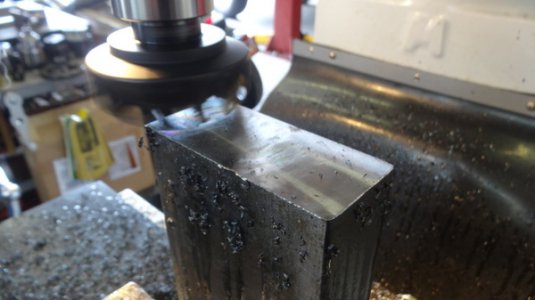

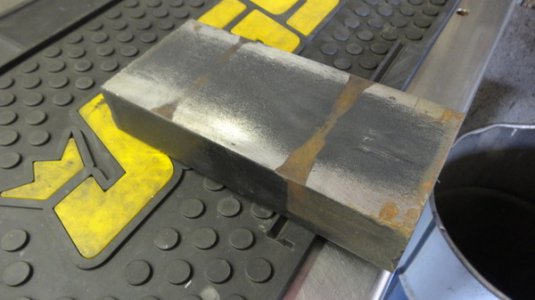

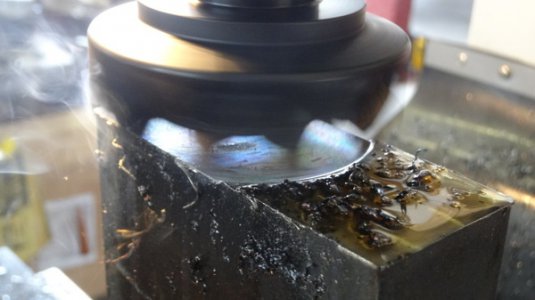

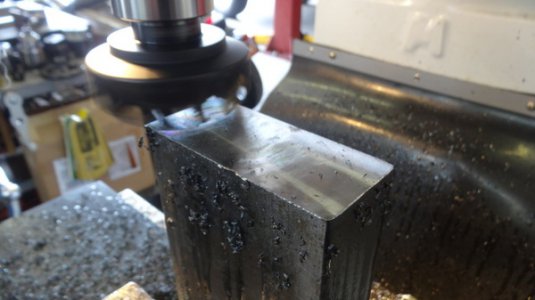

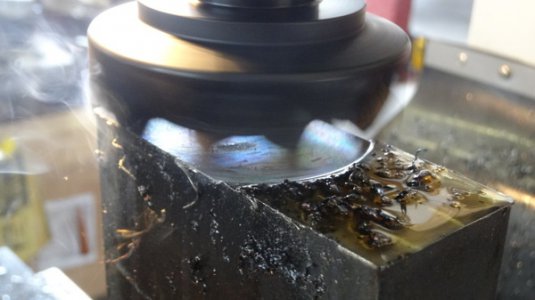

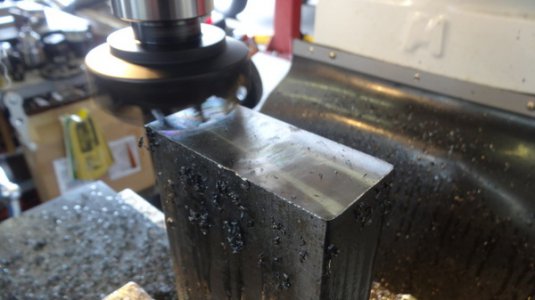

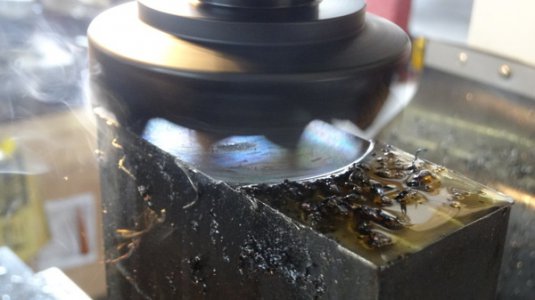

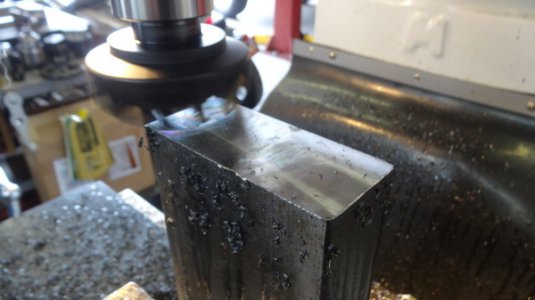

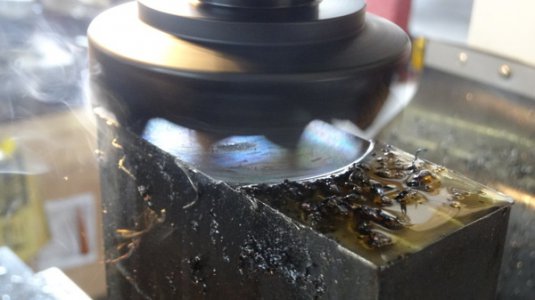

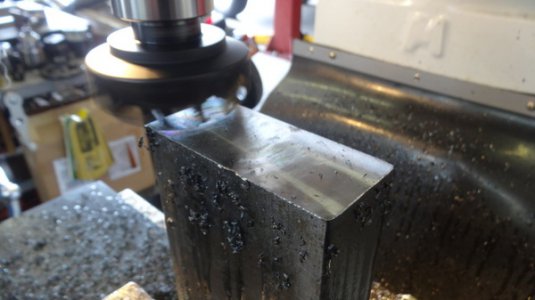

Since posting that I've been debating with myself about taking it off and cleaning again before I finish the process. Thoughts?As you can see it's higher at the near side than the far. I thought I had it very clean before I mounted it.

Sent from my SPH-L300 using Tapatalk